How to Select High Temperature Couplant Correctly in High Temperature Measurement

Use of Couplant in Industrial Inspection

Ultrasonic couplant is an essential consumable in contact ultrasonic testing. Industrial couplant is used to remove the air between the probe and the object to be tested, so that the ultrasonic wave can effectively penetrate the workpiece to achieve the purpose of detection. If poor coupling make there’s air between the probe and the workpiece to be tested, it will affect the ultrasonic wave transmission and thus affect the detection effect.

Why Use High Temperature Couplant

The reason why high-temperature couplant should be used for high-temperature workpieces is that when the normal temperature couplant contact high-temperature object, it will evaporate or dry instantly, making the ultrasonic wave difficult to reach the workpiece being measured.

The high temperature detection time is very short, and the high temperature probe can only stay on the surface of the workpiece for a short time (usually 5-10 seconds), otherwise it will reduce the life of the probe or even damage the probe. Therefore, high temperature couplant is necessary, to ensure good coupling between the probe and the workpiece and protect the probe to achieve the detection. The couplant should be applied on the probe.

How to Correctly Select High Temperature Couplant

High-temperature couplant is specially designed for ultrasonic testing in higher temperature environments and has better thermal insulation properties. Suitable for ultrasonic testing of workpieces at high temperature (above 60°C or higher).

However, as a couplant used at high temperatures, in addition to the ordinary couplant performance, it should also meet the following requirements:

It has a high working temperature range, the viscosity changes little with temperature, and is not easy to lose at high temperature.

Low volatility, suitable for long-term work at high temperature.

The composition is stable, and the physical and chemical properties don’t change when long time working at high temperature.

High Temperature Couplant Test

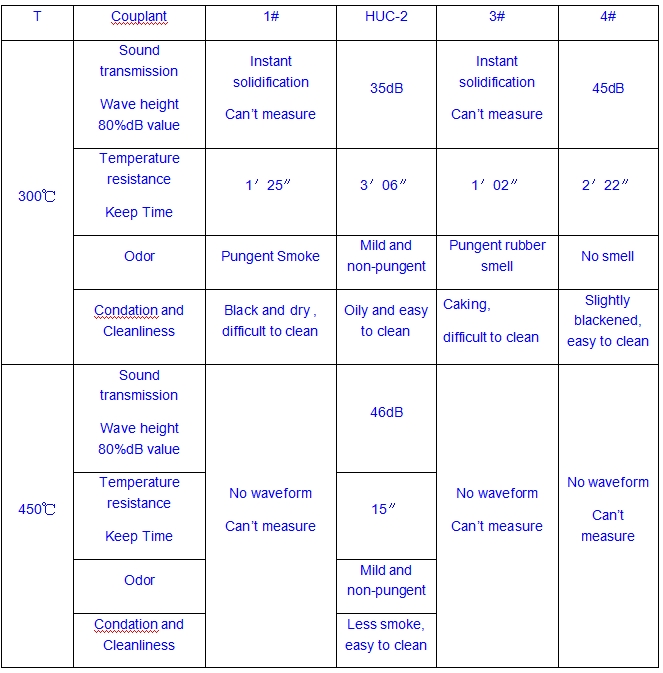

We have selected several high-temperature couplants from different manufacturers for testing. The test focuses on the temperature resistance, sound transmission, odor and cleaning of the high temperature couplant.

1#,Nominal temperature up to 550℃

2#,Nominal temperature up to 540℃

3#,Nominal temperature up to 600℃

4#,Nominal temperature up to 670℃

Test Result

Through the above tests, 2# HUC-2 high temperature couplant from YUSHI performs very well in temperature resistance, sound transmission, odor and cleaning treatment.

Good sound transmission effect, small coupling loss, which is good for ultrasonic measurement. It’s about 10dB higher than other couplants.

It has the best temperature resistance among several couplants, good fluidity, will not solidify and dry out, so can maintain the measurement.

The smell is mild and not pungent after heating, and the residue is easy to clean.

The capacity of HUC-2 is 50ml/bottle, temperature range 25~540℃, ferrous metal rust prevention grade of 90, biodegradable, non-toxic and harmless, irritating odor is small.

The above tests show that when measuring at high temperature, 1# and 3# have good temperature resistance, but poor sound transmission, and cannot be well coupled due to severe curing, not suitable for high temperature measurement. 4# has good sound transmission at 300℃ and can be used for high temperature measurement. When temperature reaches 450℃, should pay special attention to the ignition point of high temperature couplant, i.e. the auto-ignition temperature. Never use a couplant above the auto-ignition temperature. For critical or precision components, It is recommended to use a couplant that meets NDT requirements and is produced by a trusted manufacturer.