10 Reasons to Recommend YUSHI PM5 Gen2 Ultrasonic Thickness Gauge

YUSHI PM5 Gen2 ultrasonic thickness gauge is an innovative advanced ultrasonic thickness gauge with a variety of standard measuring functions and software options. This portable thickness gauge can meet most measurement needs using single crystal probes of different frequencies and different types. And the measurement range is wide, thickness from 0.15mm thin steel plate to tens of meters long steel bar, and even tens of microns thin paint layer, all can be measured.

The PM5 Gen2 is a portable and all-in-one thickness gauge that solves difficult thickness measurement problems in industries such as automotive, aerospace, military, precision manufacturing and power.

To help you get familiar with this instrument, we recommend the PM5 Gen2 thickness gauge for you mainly for the following 10 reasons:

1.Measure Thin Materials

PM5 Gen2 precision ultrasonic thickness gauge can measure materials low to 0.15mm thick with a display resolution of 0.001mm. Using the COAT measurement mode, it can measure thin paint layers of 10um.

Measure 0.150mm Thin Materials Thickness

2.Measure Thicker Materials

The large range software option of PM5 Gen2 thickness gauge is a composite measurement mode of pulse-echo method, the display range of up to 38 meters, the emphasis is on maintaining high accuracy over a large range. When measuring thick materials, the large range option is needed when the range exceeds the material thickness (300mm at a sound velocity of 5900m/s in steel). It should be noted that the maximum thickness measurement capability depends on the probe frequency, probe type and the material being tested.

Measure 1200mm Length Steel Bar Thickness

3.Display thickness of up to 5 layers simultaneously

YUSHI PM5 Gen2 thickness gauge multi-layer measurement option can simultaneously measure and display the thickness of up to five individual layers, and can also display the total layers. Common multi-layer measurement applications include: metal materials and surface coatings, multi-layer windshield glass for aircraft, etc.

Measure Automobile Multi-layer Windshield Thickness

4.High-speed measurement and simultaneous directional display

High-speed measurement and simultaneous directional display options are very important for automated measurement and high temperature measurement. With 16Hz step adjustment and window mode measurement rate up to 2kHz, it is enough to optimize your measurement workflow.

5.Display Coating Thickness and Metal Thickness Simultaneously

When measuring metal materials covered with coatings, the PM5 Gen2 thickness gauge can measure the thickness of the coating or paint layer and the net substrate separately and display them on the screen simultaneously. When the coating thickness is less than 0.100mm, the coating echo cannot be identified, so the time difference method is very useful for measuring such thin coatings.

Measure Coating Thickness and Substrate Thickness Simultaneously

6.Auto Freeze and Directional Capture Function

There are some problems when using ultrasonic thickness measurement technology for high temperature measurements or curved surface measurements.

When the high-temperature measurement temperature reaches 300℃, the high-temperature coupling agent will melt instantly, the detection time is very short, making it difficult to measure the value.

When measuring curved or concave surfaces, the contact surface will be very small,We will choose to use a probe with a small contact surface for measurement. In this case, it is difficult to keep the probe perpendicular to the surface of the measured material, resulting in small echo signal or even no echo.

At this time, we choose to use the automatic freezing and directional capture function according to the usage. When the set conditions are met during the measurement process, the waveform and value we need will be automatically frozen or automatically captured.

Application of Directional Capture in High Temperature Measurement

7.Default settings and load data to simplify the operation

When leaving the factory, PM5 Gen2 ultrasonic thickness gauge has been set up according to the default conditions of the probe for the convenience of users.

When using different probe types, the parameters of the probe settings can be directly loaded through the default settings.

When measuring the workpiece, the adjusted parameter configuration and measurement results can be stored in the instrument, the measurement data can be viewed or called at any time. When measuring again, the stored file data (including thickness values, waveforms, parameters, etc.) can be directly loaded for measurement, no need to readjust the measurement parameters, which simplifies the operation.

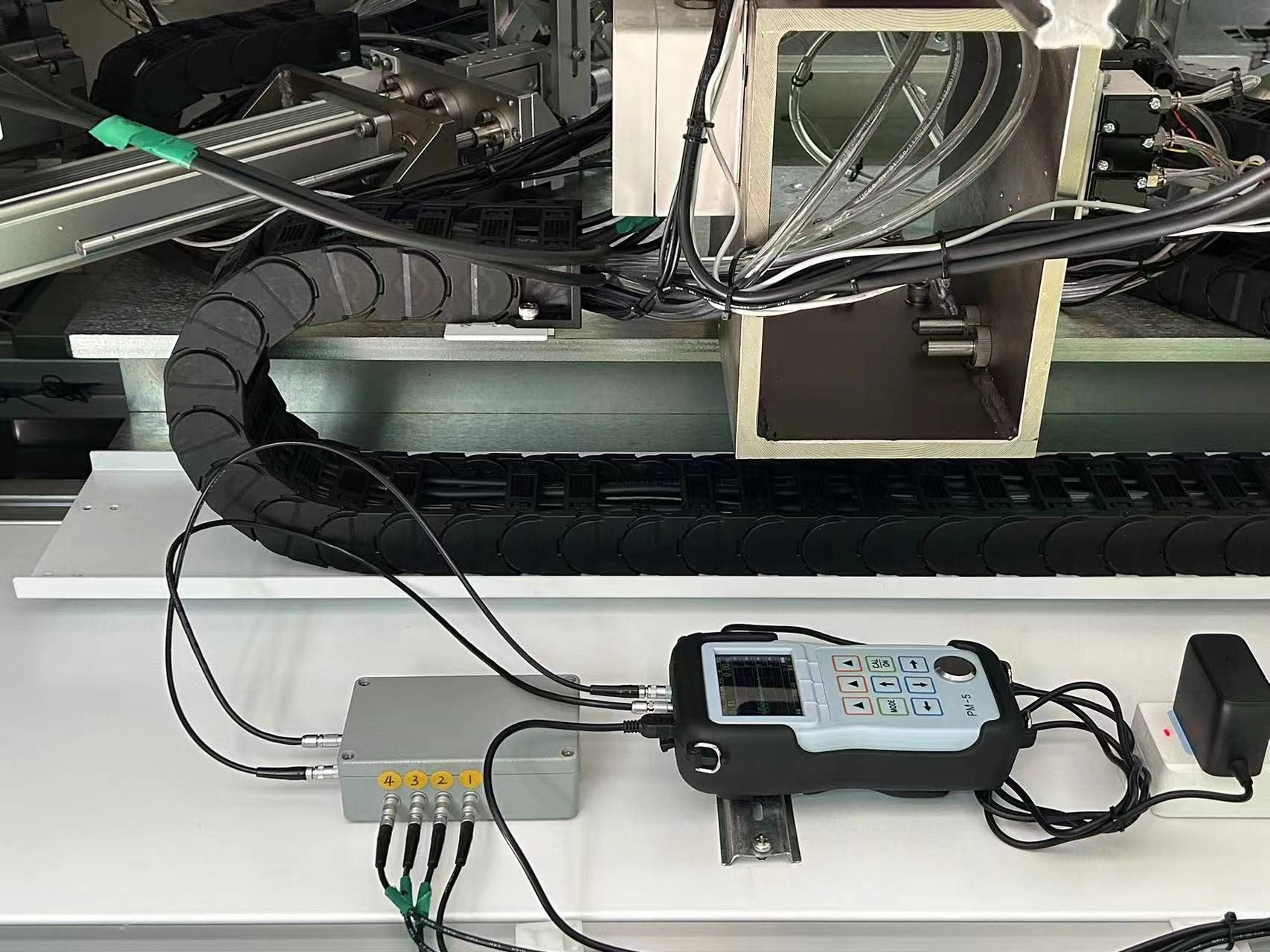

8.Multichannel Option

The multichannel option of PM5 Gen2 thickness gauge is equivalent to configuring multiple ultrasonic probes on a host to measure thickness. Through multi-channel software and external multi-channel converter, multi-point thickness values can be measured and displayed simultaneously, and the measured echo data (thickness value, waveform, parameters, etc.) can be displayed on the same screen interface.

Channel measurement saves costs, fast and efficient, mainly used in automated measurement.

Using multi-channel systems to achieve automated measurements

9.Suitable for harsh industrial environments

The sealed housing of the PM5 Gen2 thickness gauge is designed to meet IP67 dust and water resistance, and can withstand extremely humid or dusty environmental conditions. The instrument standard a rubber protective case with bracket to protect the instrument from accidental drops. It provides the best viewing angle for the screen during measurement and can be placed stably for single-handed operation.

Using the instrument in harsh environments

10. Various probes are available in different materials and thicknesses

PM5 Gen2 thickness gauge can be used with delay line probe, contact probe, protective film probe, pencil probe, immersion probe and high temperature probe. Probe frequency range in 0.5-20MHz. Probes, immersion boxes and measuring fixtures can be customized to meet various measurement needs.

The powerful function of PM5 Gen2 ultrasonic thickness gauge can solve the difficult thickness measurement problems in various industries, making the inspection work faster and more efficient.

Ultrasonic thickness gauges can be used to measure all common metal products, glass products, plastic products, ceramic products, etc. If you have problems in your measurement application, or any special measurement requirements, please contact us and we will provide you with a best solution.