Parameter Analysis of Ultrasonic Thickness Gauge

Application of Ultrasonic Thickness Gauge

Ultrasonic thickness gauge is a non-destructive testing device that uses the principle of ultrasonic pulse reflection to measure the thickness of materials (such as metals, plastics, ceramics, etc.). This technology is not only widely used in heavy industries such as petroleum, chemical, electric power, shipbuilding, aerospace, etc., but also shows its irreplaceable value in many aspects such as automobile manufacturing, construction engineering, scientific research and teaching. Whether it is testing the wall thickness of pressure vessels, evaluating the degree of pipeline corrosion, or monitoring the aging of structural materials, ultrasonic thickness gauges can provide timely and accurate data support to help staff timely discover potential safety hazards in a timely manner and prevent accidents.

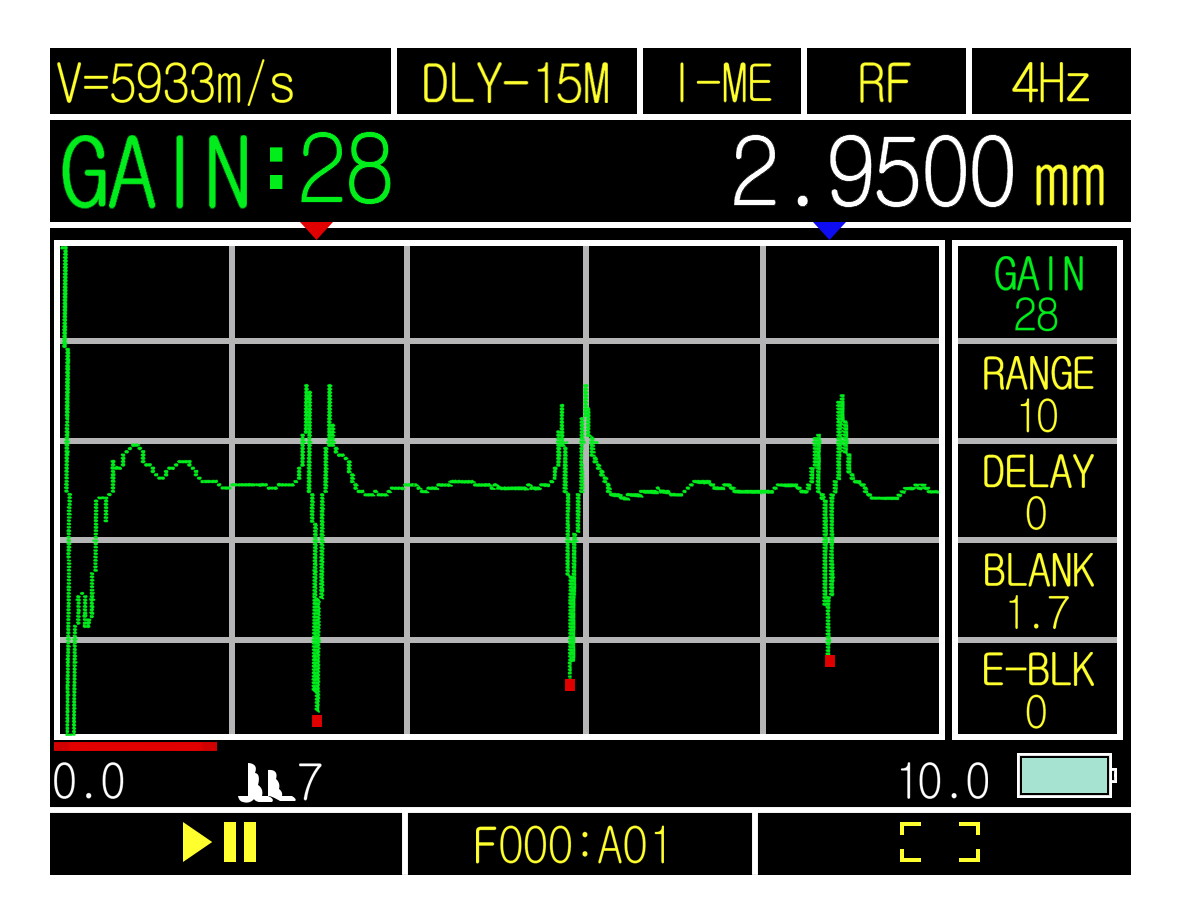

When using the ultrasonic thickness gauge, it is important to set parameters according to actual application needs to ensure the accuracy and efficiency of the measurement. Among the various parameters of an ultrasonic thickness gauge, probe frequency, resolution, and update rate are the key factors affecting its performance and accuracy. The article below will analyze these three parameters in detail to help you better understand and use ultrasonic thickness gauges.

1. Probe Frequency

Probe frequency is the nominal frequency marked on the probe, refers to the frequency of the ultrasonic wave emitted by the probe, which is related to the material and thickness of the piezoelectric chip. The choice of probe frequency directly affects the penetration of ultrasonic waves and the accuracy of measurement. Probes of different frequencies are suitable for different testing. Generally speaking, the higher the probe frequency, the higher the measurement accuracy, but the weaker the penetration; the lower the frequency, the stronger the penetration, but the lower the measurement accuracy.

High Frequency Probe:

Suitable for measuring small, thin-walled materials or samples with small contact surfaces. For example, a 20MHz delay line probe has a small diameter and can measure the thickness of a plastic bottle with a small contact surface.

Low Frequency Probe:

Suitable for measuring rough surfaces or thicker materials. For example, the 0.5MHz contact probe has a larger diameter and stronger penetration, can measure rubber thickness.

2. Resolution

Resolution is an important parameter of ultrasonic thickness gauge, which determines the accuracy of measurement results. The higher the resolution, the more accurate the measurement results. High resolution thickness gauges provide more accurate test results and can capture more subtle thickness changes.

The resolution of YUSHI PM5 Gen2 ultrasonic thickness gauge can reach 0.0001mm. For high-precision measurement, the resolution of X.XXXX should be selected.

3. Update Rate

Update rate, also known as measurement update rate, is another important parameter of ultrasonic thickness gauge, which determines the measurement speed. Higher update rate means faster measurement and can reflect the thickness changes of the measured object more timely, it’s very important for dynamic measurement or applications that require continuous monitoring.

YUSHI PM5 Gen2 Ultrasonic Thickness Gauge provides 4Hz, 8Hz, and 16Hz optional measurement update rate. Users can choose the appropriate update rate according to actual needs. When fast scan is required, a higher update rate can be selected to improve measurement efficiency.

In summary, resolution, probe frequency and update rate are the key parameters of ultrasonic thickness gauge, they together determine the performance and applicability of the thickness gauge. Probe frequency affects penetration and resolution, resolution affects measurement accuracy, and update rate affects the real-time measurement. When using ultrasonic thickness gauge, these parameters need to be considered based on specific application requirements.