Application of Acoustic Impedance In Industrial Ultrasonic Testing

Basic Concepts of Acoustic Impedance

Acoustic impedance refers to the resistance encountered by ultrasound when passing through a medium, which is usually equal to the product of the density(ρ) of the medium and the propagation speed of the sound wave(V) in the medium. The concept of acoustic impedance is proposed to understand how sound waves interact with different media. It is similar to electrical impedance in circuit theory and can provide a way to describe how materials absorb, reflect or transmit sound waves.

Acoustic impedance Z formula:

Z=ρV

The Physical Meaning of Ultrasonic Acoustic Impedance

1. Reflecting interface characteristics, when sound waves propagate from one medium to another, the change in acoustic impedance can reflect the interface characteristics between the two media.

2. Characterizing the reflection and transmission of sound waves, acoustic impedance can also be used to describe the reflection and transmission of sound waves between different media. When a sound wave travels from one medium to another, the acoustic impedance of the medium is different, causing part of the sound wave to be reflected and the other part to be transmitted.

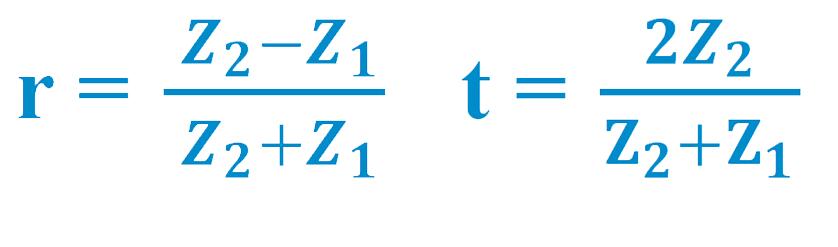

The formulas for sound pressure reflectivity r and sound pressure transmittance t are:

The Importance of Acoustic Impedance

Acoustic impedance is a key parameter in the field of acoustics. It plays a vital role in applications such as ultrasonic imaging, sonar, and design of sound-absorbing materials.

Acoustic impedance is very important in industrial nondestructive testing. It affects the incidence and reflection efficiency of ultrasonic waves on materials, and thus affects the results of ultrasonic testing.

Application Examples of Acoustic Impedance In Industrial Detection

As a conventional nondestructive testing method, ultrasonic testing is widely used in industrial non-destructive testing of homogeneous materials because of its advantages of strong penetration, high detection sensitivity and low detection cost.

1

★In the process of ultrasonic propagation, the concept of impedance is used when the properties of each layer of material in the workpiece are different and when they interact with the boundary.

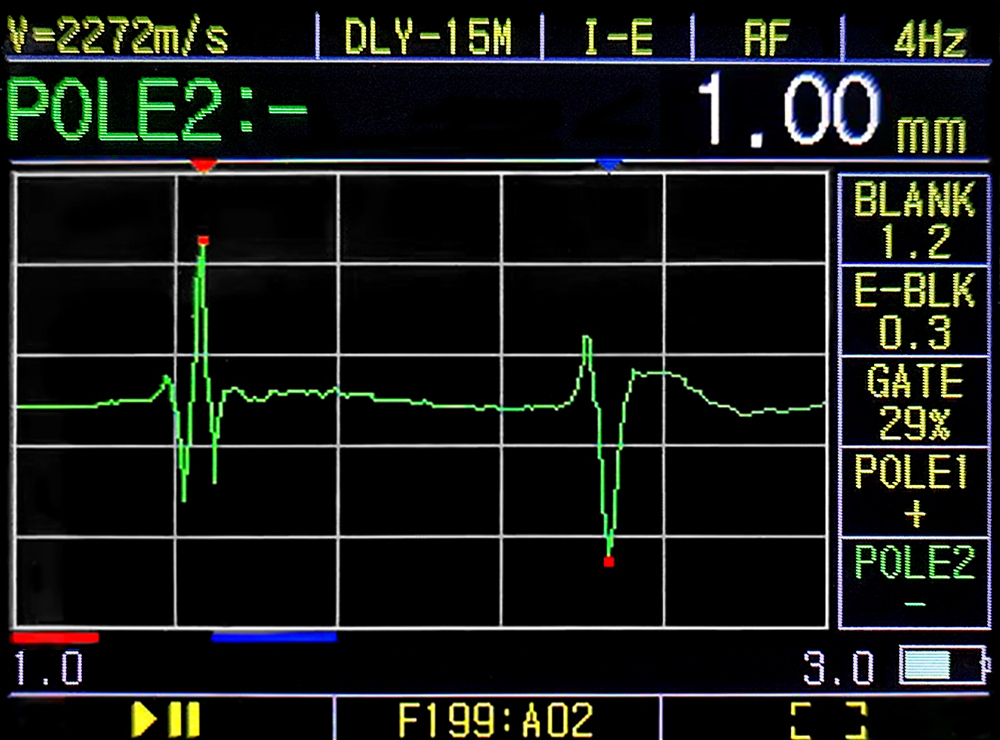

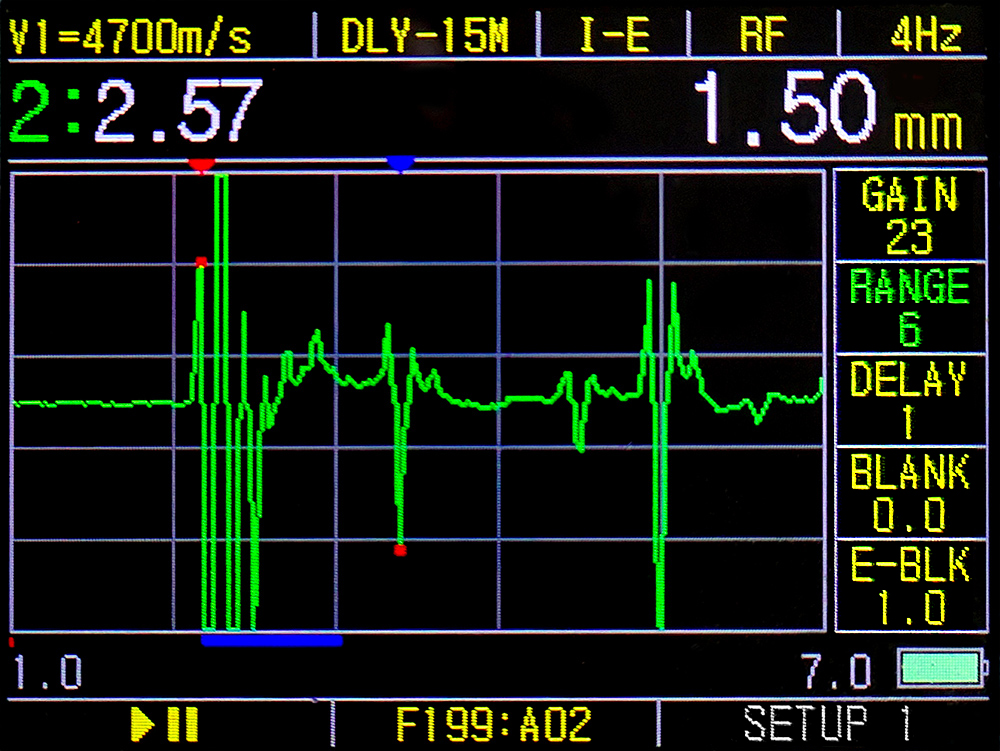

Negative peak echo between plastic and air interface

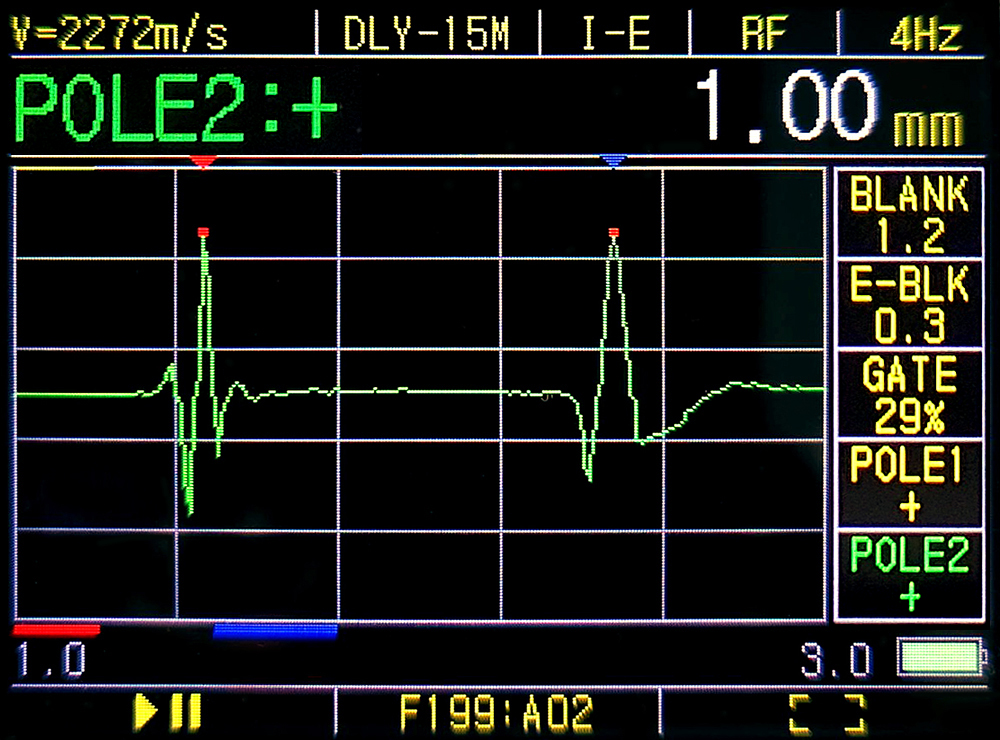

Positive peak echo between plastic and steel interface

When measuring material thickness, the polarity of the echo is positive above the baseline and negative below the baseline. The polarity depends on the acoustic impedance of the materials on both sides of the interface.

Normally, the medium on the back of the measured workpiece is air or liquid, and the acoustic impedance of air and liquid is lower than that of metal, ceramic or plastic, and the echo polarity is negative. However, if the glass or plastic layer on a metal surface is measured, the acoustic impedance relationship between the two materials is reversed, and so is the polarity of their echoes. We couple plastic to metal, In which case the relevant echo polarity settings need to be changed to maintain the accuracy of the measurement.

In actual measurement, if the positive and negative echoes cannot be clearly defined due to special material conditions, it is necessary to use a standard test block for comparison to determine the measurement accuracy.

2

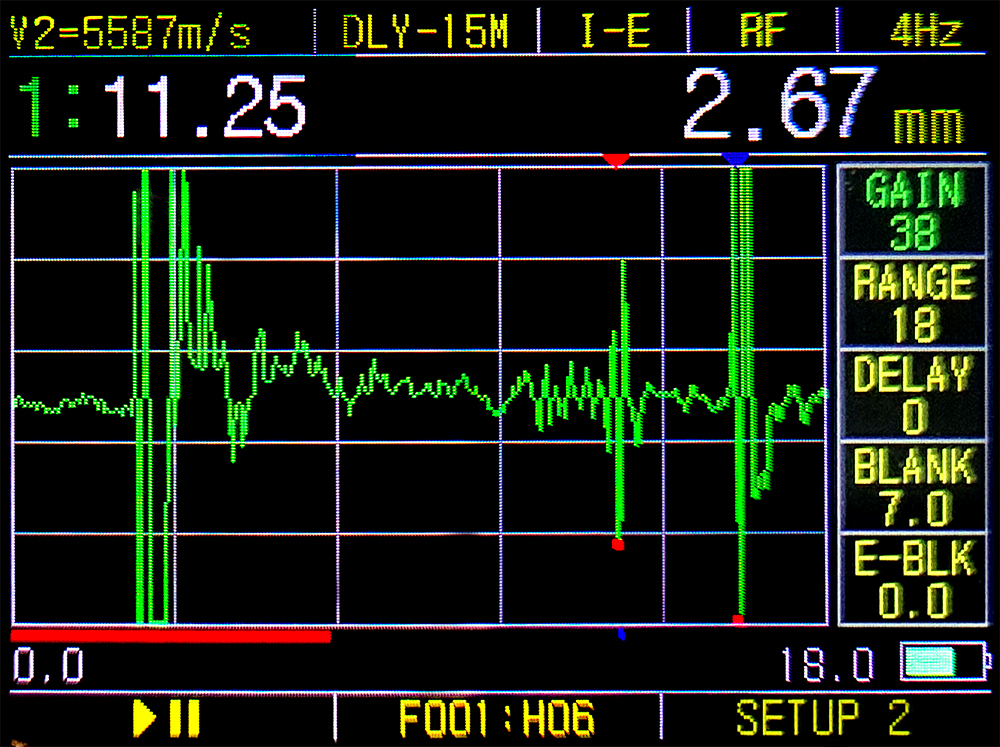

★When we measure composite metal material, the more different the acoustic impedance (Z) between the two composite metal materials, the more energy is reflected at the boundary of the two media, the clearer the interface echo, and the easier the layer thickness will be measured. On the contrary, the closer the acoustic impedance (Z) between the two composite metal materials, the stronger the transmission, the weaker the reflection, and the echo of the interface is small or even no no echo. YUSHI PM5 Gen2 ultrasonic thickness gauge can provide you with best measurement solutions.

Interface echo of steel and stainless steel with similar acoustic impedance

Interface echo of copper and aluminum with large different acoustic impedance

3

★In ultrasonic testing, the acoustic impedance matching of the ultrasonic probe is very important for the quality of ultrasonic testing. By properly selecting a couplant or using a matching layer, the acoustic impedance can be matched, the propagation efficiency of ultrasonic waves can be improved, so as to obtain clearer and more accurate ultrasonic testing results.

4

★By measuring the acoustic impedance of a material, information about its density and the speed of sound can be inferred, which can help identify the material or assess its properties.

Understanding acoustic impedance helps design materials and devices that optimize ultrasonic transmission and reflection in various applications, improving the effectiveness of ultrasonic testing. For ultrasonic applications, we should understand the acoustic impedance matching, select the correct probe, and set the correct echo polarity to maintain measurement accuracy.