Ultrasonic Thickness Gauges Measures The Thickness of Rubber Conveyor Belt with Reinforced Layers

1. Characteristics and Applications of Rubber Conveyor Belt

Rubber conveyor belt is a conveyor belt made of rubber. It is a widely used transportation machinery in industrial production, used to transport various materials to meet industrial needs. Rubber conveyor belt has the advantages of lightness, wear resistance, oil resistance, acid and alkali resistance, aging resistance, and high tensile strength. Among which wear resistance and oil resistance are its most important advantages.

Widely used in mining, steel smelting, building materials cement, port terminals, thermal power generation and other fields of material transportation, plays an important supporting role in the development of key national economy.

2. Structure and the importance of quality control

The conveyor belt is the main component of the belt conveyor. From the structure composition, the conveyor belt is mainly composed of three parts: skeleton material, cover layer and base material. Heavy conveyor belts have an inner layer of fabric or steel cord to enhance the bearing strength of the conveyor belt.

During the production process and after installation, the thickness of the conveyor belt is one of the important indicators to ensure that the product meets the relevant specifications, among which the rubber layer is the key part to determine its performance and use.

During use, the conveyor belt will wear and become thinner. If it is not controlled, in addition to conventional damage, it will also cause breakage, which will not only bring huge economic losses, but even cause safety accidents in serious cases. It is very important for users to regularly test the thickness of the remaining rubber of the conveyor belt to estimate the service life of the conveyor belt and take targeted control measures.

3. Sample

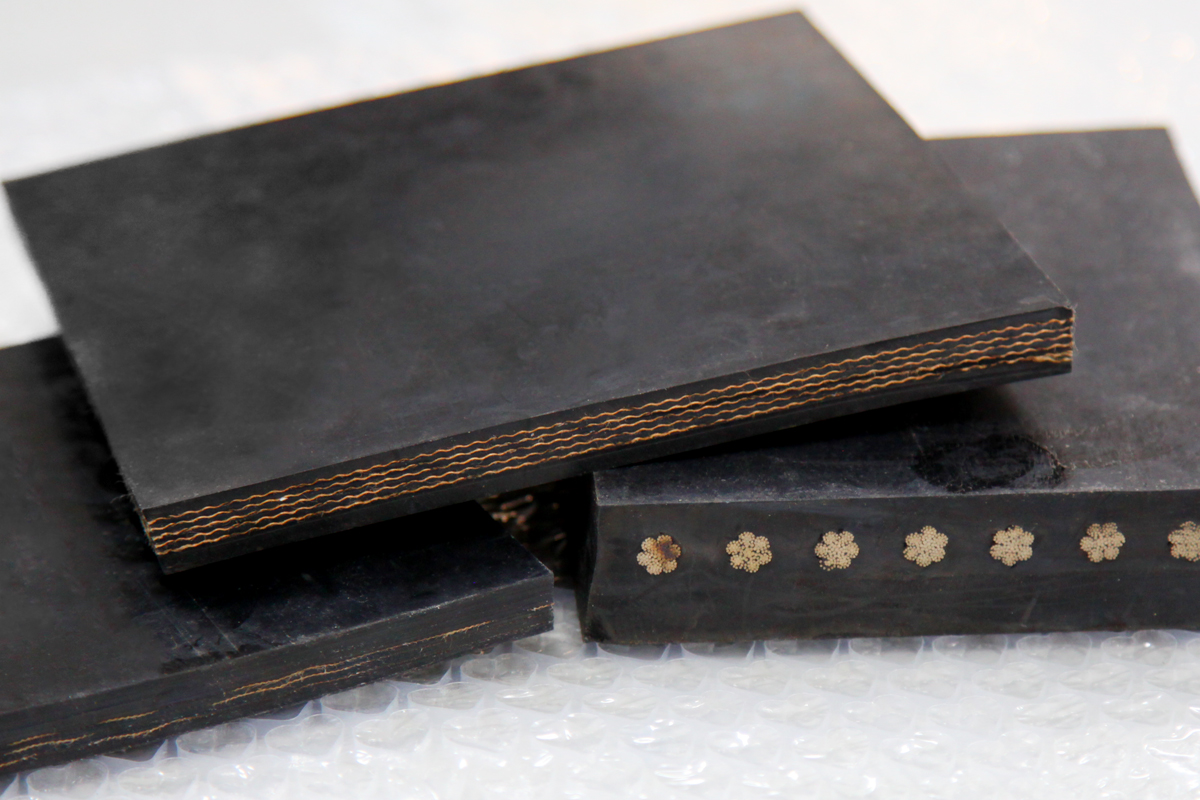

Our user is a rubber products company specializing in the production and processing of conveyor belts, mining machinery equipment and accessories.

We received a rubber conveyor belt sample from the user and they need to know the rubber thickness on the reinforcing layer and the entire thickness of the conveyor belt.

4. Measurement and Analysis

During the measurement, the ultrasonic wave passes through the rubber coating to the reinforcing layer and reflect back, so we can get the thickness of the rubber coating. If the reinforcing layer of the conveyor belt is a textile material, the ultrasonic wave cannot penetrate the textile material to the underlying rubber. So it is difficult to get the overall thickness of the conveyor belt.

For conveyor belt with steel cord reinforcement, the overall thickness of the conveyor belt can be measured only when there are wide enough gaps between the steel cords to allow the ultrasonic waves to propagate unimpeded to the other side of the conveyor belt.

5. Measuring Result

We take the measurement by YUSHI PM5 Gen2 ultrasonic thickness gauge. The choice of probe depends on the thickness range of the rubber layer to be measured. If the thickness range of the rubber layer to be measured is between about 1 mm and 6 mm, a 2.25MHz delay line probe (C2.25M13) is recommended. If the rubber layer thickness range is between about 6 mm and 25 mm, a 2.25MHz contact probe (C2.25M13) is recommended. We can also measure thicker rubber layers with a 0.5 MHz (0.5M28) low-frequency probe, up to 60 mm for standard and up to 120 mm for customization.

When measuring thickness, it is necessary to observe the measurement through the real-time A-scan waveform to find the correct bottom echo of the material so that the thickness measurement is correct and effective. For conveyor belts with wide enough gaps between steel cords, we can use double layer option to view the coating thickness and overall thickness simultaneously through the waveform.

★Attention: Rubber materials have strong attenuation, so gel couplant is recommended to use. Before testing the conveyor belt in service, the conveyor belt should be cleaned.

Measure the thickness of thin rubber coatings on reinforced layers

Simultaneously measure coating thickness and overall thickness using the double layer option

Measuring material thickness with ultrasonic thickness gauge is the main means and method for controlling product quality. If you want to learn about the method of measuring the thickness of rubber conveyor belts using ultrasonic technology, or if you have any problem in the measurement, please feel free to contact us to send samples for testing, we will offer you the best measurement solution.