Application of Ultrasonic Thickness Gauge in Silicon Carbide Material Measurement

What is Silicon Carbide?

Silicon Carbide (SiC), as known as carborundum, is a hard chemical compound containing silicon and carbon, with high temperature stability, high hardness, corrosion resistance and so on. These characteristics make sic have important application value in many fields, especially in energy, electronics, semiconductors, smart grid, photovoltaic inverters, ceramics and coatings. Silicon carbide materials are widely used and have huge market potential.

In recent years, SiC has become an important player in the semiconductor industry. As a multifunctional material, silicon carbide plays a unique advantage in various fields and promotes innovation and development in many fields.

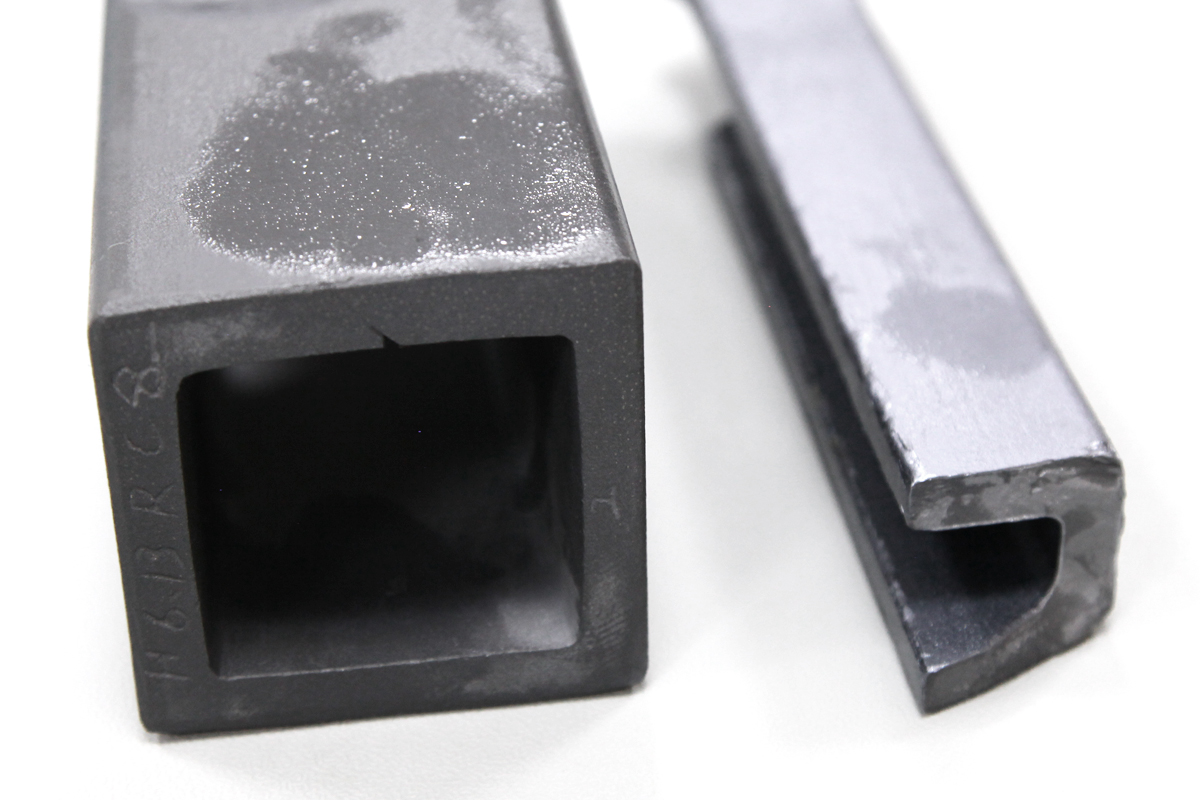

Silicon carbide brick is refractory product made of silicon carbide as the main raw material. Generally, black silicon carbide (SiC content above 96%) is used as the raw material, and a binder (or no binder) is added, and it is made through the processes of batching, mixing, molding and firing. It has the characteristics of good wear resistance, good corrosion resistance, high temperature strength, good thermal shock stability, high thermal conductivity, small thermal expansion coefficient and so on.

Properties and Applications of Silicon Carbide Bricks

Silicon carbide brick is a very important refractory material and has many uses. In the industrial field, silicon carbide brick is widely used in the construction of high-temperature furnaces, melting furnaces, crucibles and other refractory components. Silicon carbide brick has excellent high temperature resistance and can withstand thermal stress and thermal shock at extremely high temperatures, so it is very reliable to use in high temperature environments.

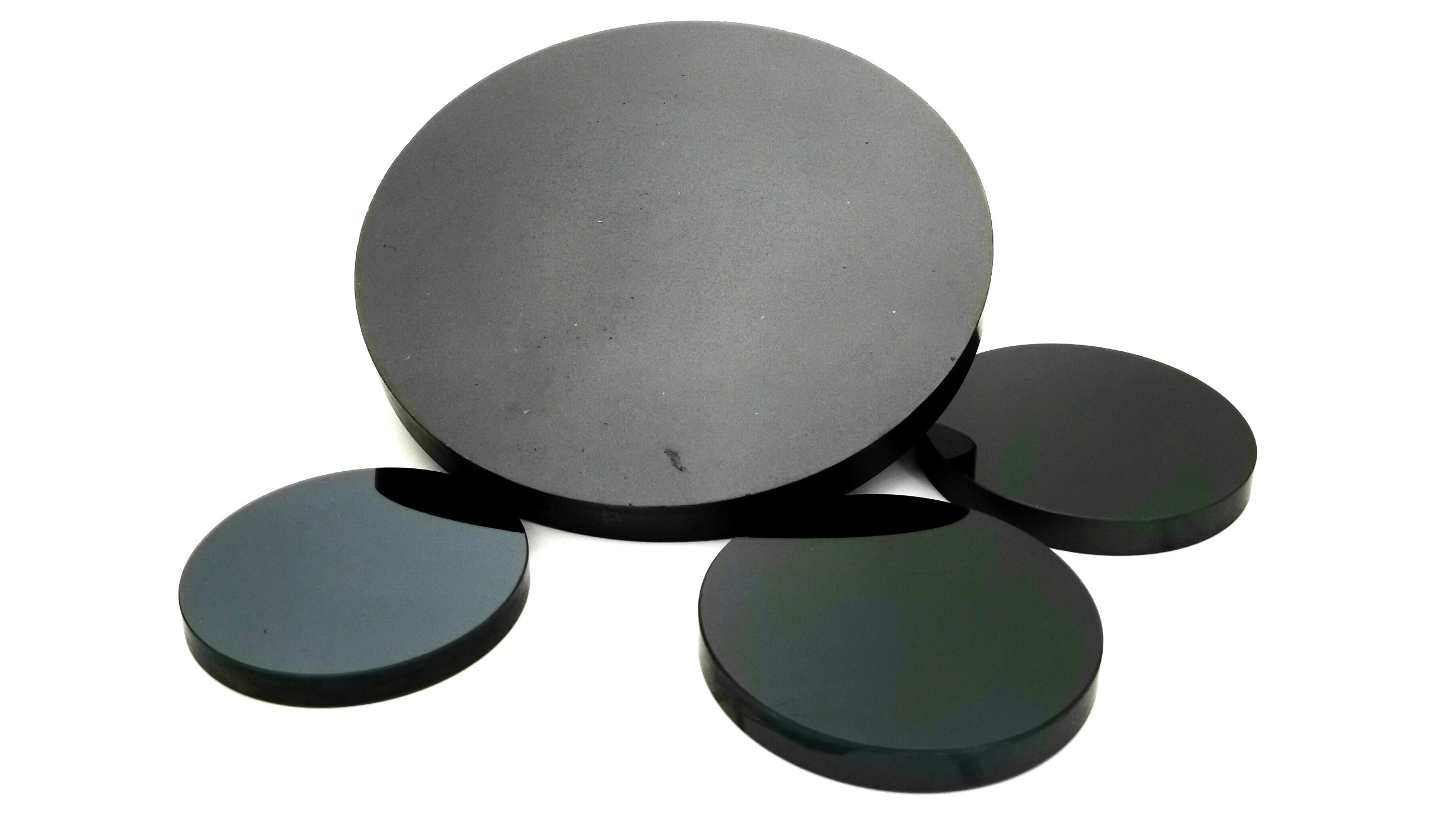

Samples

Our user is a domestic enterprise that focuses on the R&D, manufacturing, sales and service of high efficiency solar cells. The company is committed to providing customers with high performance, high reliability solar cell products that meet IEC double standards.

Silicon solar cells are mainly based on semiconductor materials. Their working principle is to use photovoltaic materials to absorb light energy and then produce photovoltaic reactions. Silicon is the most ideal solar cell material, which is the main reason why solar cells are mainly made of silicon materials. Silicon carbide (SiC) has many advantages over silicon in solar power generation applications.

Measurement Analysis

The quality control and inspection standards of silicon carbide are important means to ensure product quality. By strictly following the quality control process, product stability and reliability can be effectively guaranteed. At the same time, inspection and testing according to relevant quality inspection standards can evaluate whether the product meets the specified technical requirements.

The customer requested to measure the thickness of the sample and to assist the flaw detection methods to determine the cracks inside the material.

Measurement Result

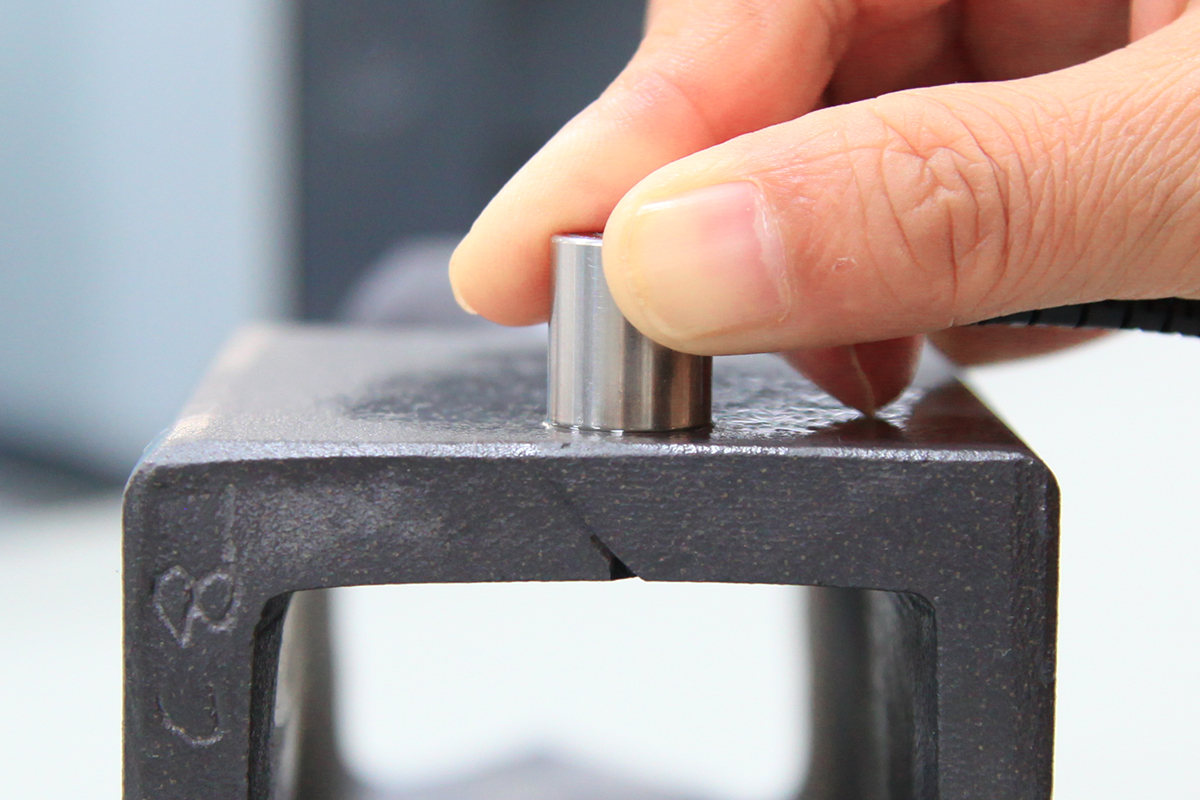

We use YUSHI PM5 Gen2 ultrasonic thickness gauge and C5M13 contact probe for measurement. When measuring thickness, we need to observe the measurement through the real-time A-scan waveform to find the correct bottom echo of the material to ensure that the thickness measurement is correct and effective. The location of the internal crack can also be found through the waveform changes.

Measure material thickness by ultrasonic thickness gauge is the main method for controlling product quality. If you want to learn more about the ultrasonic technology to measure the similar products’ thickness, or any problems in measurement applications, please feel free to contact us to send samples for testing, we will offer you with best solutions.