Application of Ultrasonic Thickness Gauge in Carbon Fiber Material Measurement

Carbon fiber is a material that is stronger and harder than metal and glass fiber, so it can be used to make lighter products. Carbon fiber composite materials are important reinforcing materials in advanced composite materials. Using carbon fiber composite materials to make parts can not only reduce weight, but also achieve a series of advantages such as energy saving and emission reduction, speed up production, improve product quality, reduce loss, and extend equipment life.

Lightweight Applications of Carbon Fiber Materials

Carbon fiber materials are widely used in the defense industry and are indispensable strategic materials for advanced equipment such as military aircraft, drones, military boxes, rockets, missiles, satellites and ships, etc. They are also widely used in civil fields such as wind power generation, sports and leisure, transportation, automobile industry, energy, chemical industry, and construction.

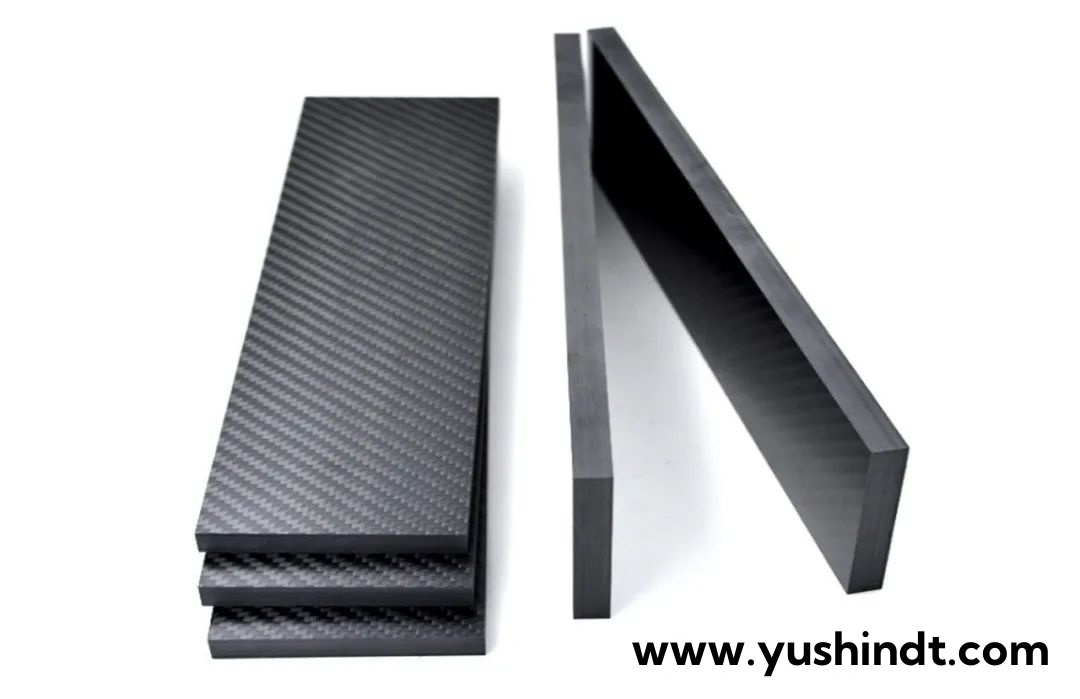

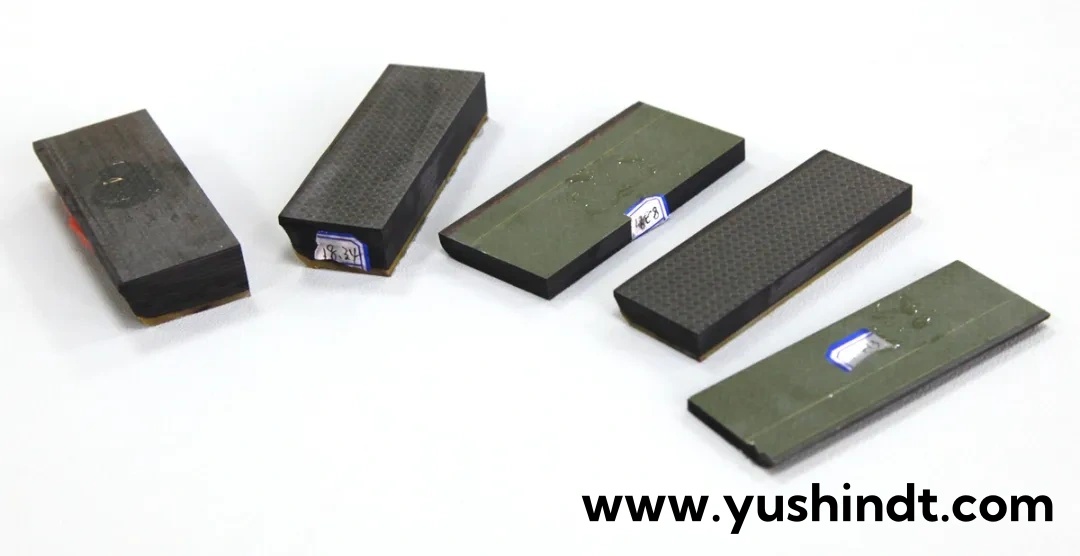

Sample

★The sample is a carbon fiber sheet of about 4-20mm, need to measure its thickness.

We received a sample from a user, who is professional engaged in the development and production of carbon fiber reinforced composite products. The company's business covers aerospace, ship, electronics and other military - civilian integration fields.

Measurement Analysis

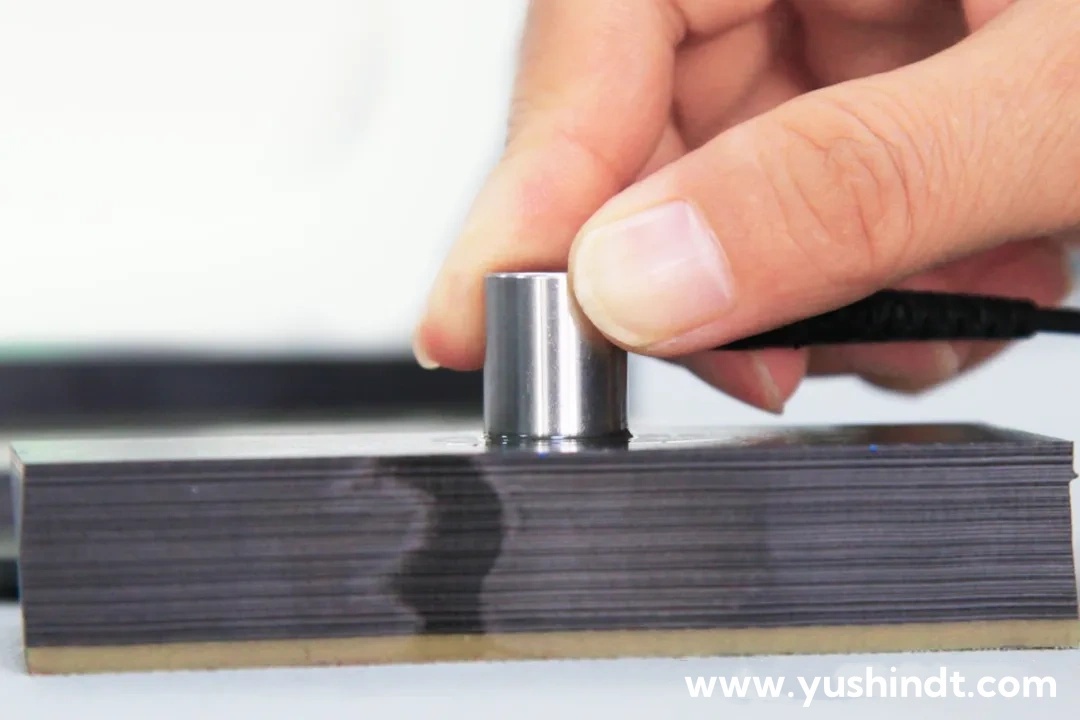

For carbon fiber composites, ultrasonic testing technology is the most widely used non-destructive testing technology. Ultrasonic have strong penetrating power, good directivity, high sensitivity, and harmless to human body, more suitable for the detection of internal defects of composite materials.

Commonly used carbon fiber sheets thickness is around 0.5-5.0mm. The thickness of the carbon fiber sheet is related to the number of layers. You need to stack multiple layers if you want to get a thicker carbon fiber sheet. The more layers or the thicker the thickness, the greater the micro cracks between the layers. If the carbon fiber sheet produced in this way has cracks, there may be a risk of breakage in use.

It is very important to use ultrasonic thickness gauge to detect whether there are cracks or faults in carbon fiber materials and measure whether the thickness meets the standards to ensure the performance of the products in practical applications.

Measurement Result

The ultrasonic thickness measurement method can be used for real-time measurement on site.

It is a very important and effective method for measuring the thickness of composite materials.

We use YUSHI PM5Gen2 ultrasonic thickness gauge with a 5mhz single contact probe to measure, The structural of carbon fiber composites is characterized by stratification and voids. When we measure the thickness, we need to observe the measurement through real-time A-scan waveform to find the correct bottom echo of the carbon fiber, then the measured value will be correct.

Ultrasonic thickness gauge is the main method to control the quality of carbon fiber composites. If you want to learn about the method of using ultrasonic technology to measure similar products, or if you have problems in the measurement application, please contact us to send samples for testing, we will help you with a solution.