YUSHI PR10 Ultrasonic Pulser-Receiver

The PR10 developed by YUSHI INSTRUMENTS is a computer-controlled ultrasonic pulse generator and receiver with excellent performance. It is used to connect ultrasonic probes and oscilloscopes, it can help with ultrasonic flaw detection, thickness measurement, probe inspection, etc. It has wide range in non-destructive testing, material analysis and other fields.

The pulse generator receiver includes a control program software based on the Windows system, which can select the trigger source, transmission voltage, repetition frequency and pulse width, and can also switch the single/dual mode of the receiver, adjust the damping and gain to meet the different needs of users. Users can also use the open SDK software development kit to develop their own applications under various mainstream Windows systems.

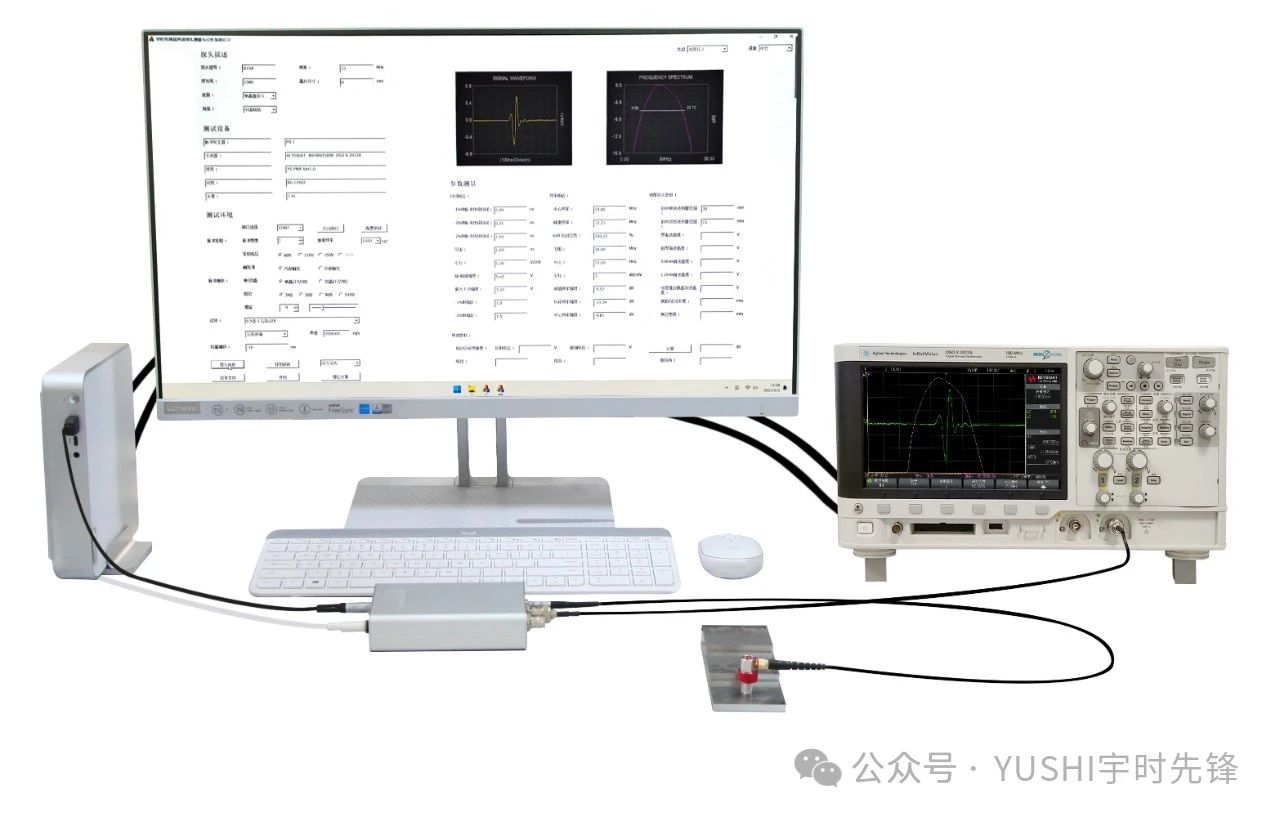

01 Replace Traditional Pulse Generator Receiver

The PR10 ultrasonic pulser and receiver developed by YUSHI INSTRUMENTS for customer needs has an overall size of 14cm*8.8cm*3cm. Small size, light weight, Simple operation, comprehensive function and reliable performance. Users have very good feedback after using it, it can well meet their needs, can completely replace the imported traditional generation and receiving devices. Users can also enjoy affordable prices while pursuing high-performance products, reducing the cost.

02 Control Program Software for Windows

The ultrasonic pulser receiver control software doesn’t require additional installation or configuration. Users can directly run the executable file without worrying about the complicated installation process. The interface is more simple and easy to operate, and the appropriate parameter Settings are selected according to the requirements. You can also choose to save the current parameter settings to a file, and open the file for next use, the current parameter settings can be synchronized.

03 Create An Ideal Testing Platform

The pulser receiver signal output interface is used to connect the oscilloscope to display the received waveform; Probe interface is used to connect single and double crystal ultrasonic probes; communication interface is used to connect computer, through the control software on the PC, to provide an ideal test platform for ultrasonic flaw detection, material thickness measurement, probe characteristic analysis, special material characteristic analysis, etc.

04 Application of Test Platform in Non-Destructive Testing and Other Fields

1.Probe Performance Test

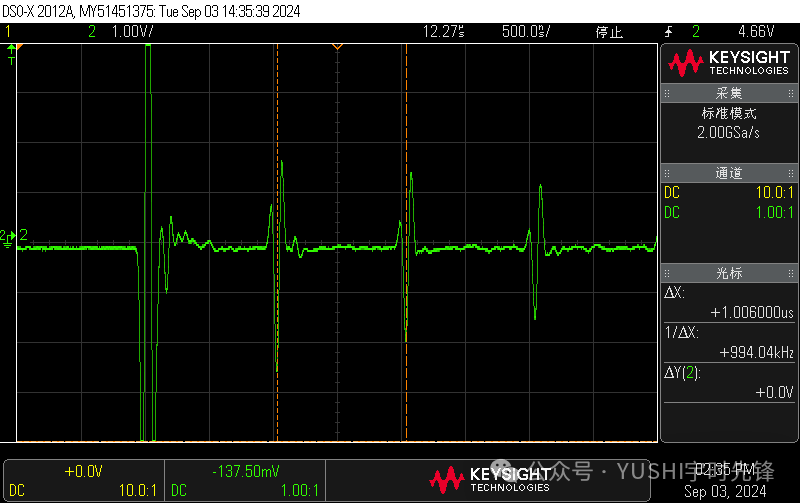

Probe is very important in the process of ultrasonic testing, probe performance directly affects the accuracy and reliability of the test results. The test platform can measure and analyze the time domain response and frequency domain response of the echo signal of the probe in working state.

2.Ultrasonic Flaw Detection and Thickness Measurement

The waveform is measured and analyzed based on the ultrasonic pulse reflection principle. Flaw detection is to determine the presence, size and location of defects. Thickness measurement is to obtain the workpiece thickness by the known material sound velocity and the time interval between two echoes.

3. Material Analysis

Using the principle of ultrasonic pulse reflection, the mechanical properties and quality of materials are evaluated by measuring the speed of ultrasonic wave propagation in material, which is widely used in the field of materials engineering, especially in material evaluation and quality control.