YUSHI Ultrasonic Probe Cable

Cable Type: RG58 Coaxial Cable

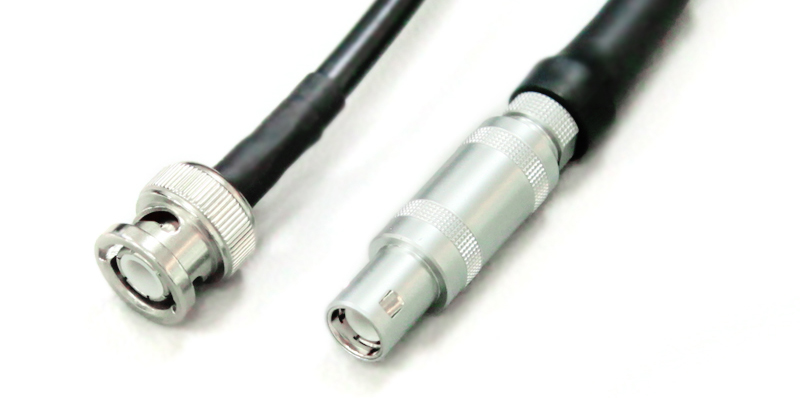

Connector Type: BNC, LEMO 1

Standard Length: 1 Meter

The cable, also called ultrasonic probe cable, is a high-frequency coaxial cable used to connect the ultrasonic probe and the ultrasonic flaw detector/thickness gauge. This coaxial cable can eliminate the influence of external electromagnetic waves on the excitation pulses emitted by the ultrasonic probe and the echo pulses received, and prevent the high-frequency pulses in the probe cable from radiating outward in the form of electromagnetic waves.

In order to ensure product quality, we take effective quality control measures in every link, and strictly control the selection, pretreatment, crimping or welding, and testing of cables and connectors, can completely replace imported original cables. This allows our customers to enjoy affordable prices while pursuing high-performance products.

Cable Connector

Cable connectors are widely used in electronic products such as instruments and meters. They are key products to ensure the correctness and reliability of signal transmission.

★Dedicated BNC and LEMO 1 connectors (matching RG58 cables). The universal interface has strong compatibility and is convenient for connecting ultrasonic flaw detectors and probes from different manufacturers.

★The BNC series is inserted and fixed by tightening the bayonet of the connecting wire connector. The LEMO series is plug-in type and can be used directly after insertion without clamping or tightening.

Cable

Our cable uses RG58 coaxial cable, which has the greatest characteristics of good anti-interference ability and stable data transmission.

★RG58 coaxial cable is a high-quality cable designed for a variety of communication and signal transmission applications. The impedance rating of this cable is 50 ohms and it is optimized to effectively transmit signals while minimizing signal loss and interference, making it ideal for analog and digital systems. It has the advantages of high and low temperature resistance, UV resistance, flame retardant, good shielding performance, and long service life.

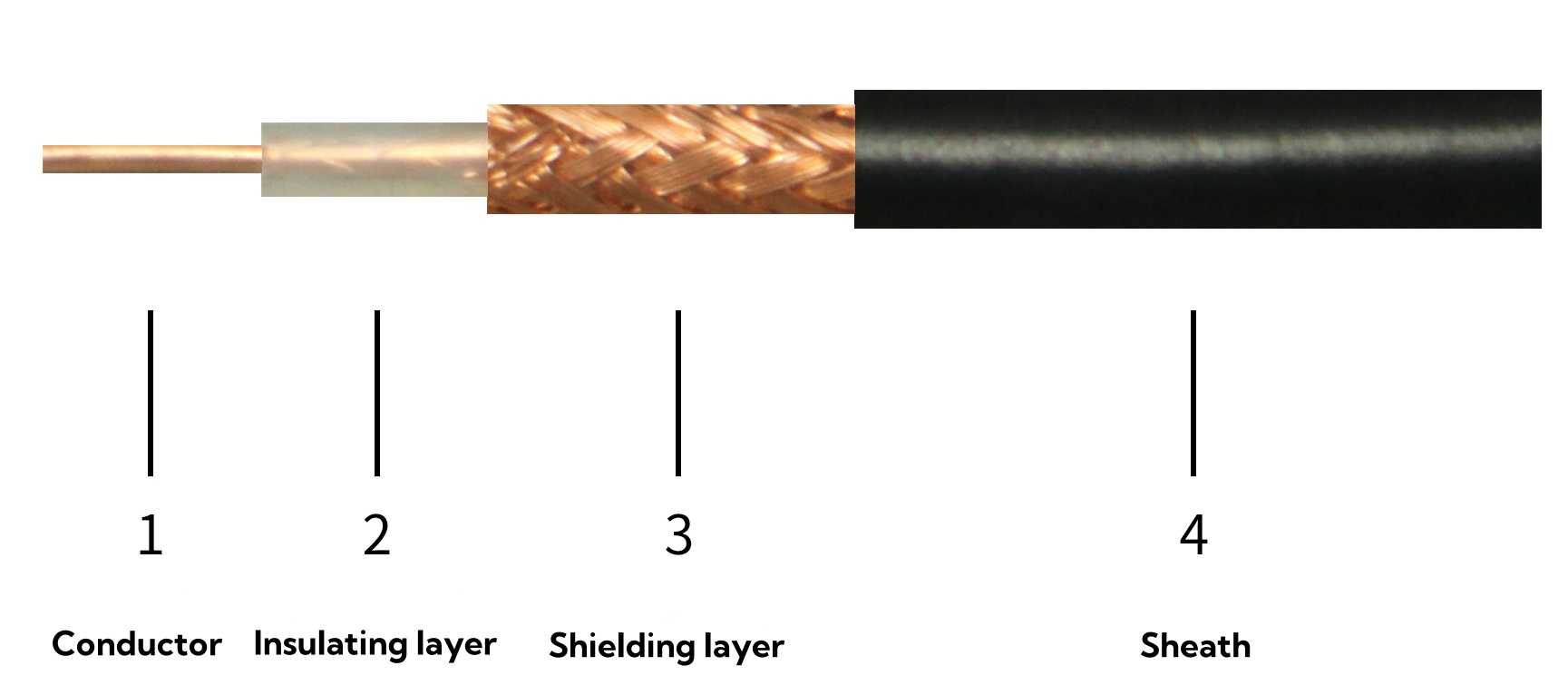

★Coaxial cable structure: The components of coaxial cable from the inside to the outside are conductor, insulation layer, shielding layer and sheath.

1. Conductor-The material is copper conductor. Copper wire has good flexibility, good conductivity, good stability, and corrosion resistance, which can greatly extend the cable service life.

2. Insulating layer - Polyethylene (PE), is a thermoplastic resin, non-toxic and harmless, excellent low temperature resistance, and can withstand corrosion from most acids and alkalis, has excellent electrical insulation properties.

3. Shielding layer - copper wire braided shielding mesh, which is flexible, wear-resistant and conductive. Ensure the signal transmission performance in electromagnetic interference environment.

4. Sheath - polyvinyl chloride (PVC), has good mechanical properties, good flexibility, quite strong, self-extinguishing, has strong acid and alkali resistance, and has good chemical stability.

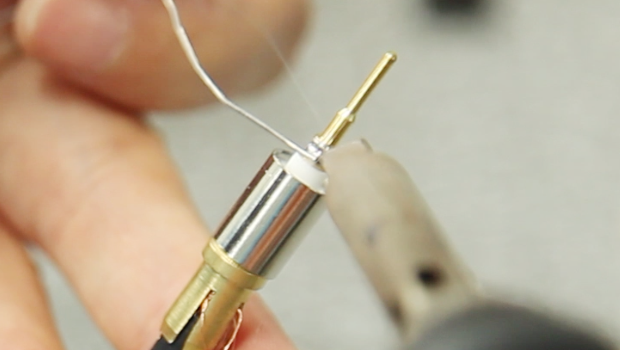

Strict Production and Assembly Process

★If there is a problem with the quality of assembly, such as the ground wire is broken, short circuit between the cable core and the core, or between the core and the electrical connector shell, the connector has poor contact or bad termination, etc., it will seriously affect the reliability of electronic products. Therefore, effective quality control measures should be taken for the assembly process of cable connectors.

★During the assembly process, special tools are used to install connector accessories, and the wire cores and pins are welded to ensure reliable connector connection.

Application

Probe cable is an important consumable in ultrasonic flaw detection and is used to connect the ultrasonic flaw detector/thickness gauge and the ultrasonic probe.

YUSHI produces nearly 100 different types of ultrasonic probe cables (connectors include BNC \ LEMO 1 \ MINIBNC \ LEMO 00 \ Subvis \ Microdot, etc.), default length is 2 meters, special length and connector type can be customized. Users can also choose from a variety of cable levels to meet specific application requirements. The impedance of all cables is 50 ohms. If you need special or customized cables, please contact us.