Ultrasonic Thickness Gauge Measures The Thickness of Power Cable Inner Sheath Layer

Power Cable Introduction

Power cables are used for transmission and distribution of electric energy, often used in urban underground power grids, power station lines, industrial and mining enterprises internal power supply and underwater transmission lines across the river and sea. In the power line, the proportion of cables is gradually increasing.

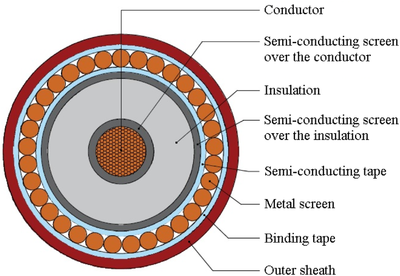

The components of power cables are: conductor, conductor shield, insulation layer, insulation shield, sheath layer, anti-corrosion asphalt, and outer protective layer.

The materials of power cables sheath can be divided into metal materials and non-metal materials. Metal materials include copper, aluminum and lead sheath. Non-metal sheaths include polyethylene, nylon, silicone rubber, TPE, etc. The main function of the inner sheath of the cable is to protect the core wire from water and moisture, prevent the core wire and the insulation layer from external damage, and to have a certain anti-corrosion effect. The outer sheath is to protect the insulation layer from external mechanical damage and chemical corrosion, enhance mechanical strength and increase service life.

Product Sample

We received a power cable with a metal inner sheath from a customer. From the above we know that the main function of the inner sheath is to protect the core wire inside, which requires it have good sealing and uniform thickness to meet certain standards.

Manufacturers need to strictly control the thickness of the metal inner sheath during the production. Using an ultrasonic thickness gauge to measure its thickness and uniform is the main method of controlling product quality.

Measuring Result

We use YUSHI PM5 Gen2 ultrasonic thickness gauge with single crystal delay line probe for testing. We got clear and stable waveform and measured value. The thickness of the metal inner sheath was about 3.3mm, and the thickness was uniform. Meet customer's production process standard requirements.

If you have the same measurement requirements in your application, or have problems in your measurement, please feel free to contact us and we will provide you with best solutions.