The Best Choice For Rapid Measurement of Nodular Cast Iron Spheroidized Rate is Ultrasonic Thickness Gauge

Nodular Cast Iron

Nodular Cast iron is a kind of high strength cast iron material developed in the 1950s, based on its excellent performance, it has been successfully used to cast some complex forces, strength, toughness, wear resistance requirements of high parts. Nodular Cast iron has rapidly developed into a material second only to gray iron and widely used.

Spheroidization Rate

The spheroidized rate is the key to the quality of nodular cast iron, and it is also the focus of metallographic inspection. High spheroidized rate, the material tensile strength, plasticity, wear resistance are high. The spheroidized level of ordinary nodular cast iron in China requires more than 4, (the spheroidized rate of 70%), general casting factory the spheroidized rate achieved is about 85%. In recent years, with the development of nodular cast iron production, especially in industries with high requirements for wind power casting production and casting quality, the spheroidized level is required to reach level 2, that is the spheroidized rate is more than 90%.

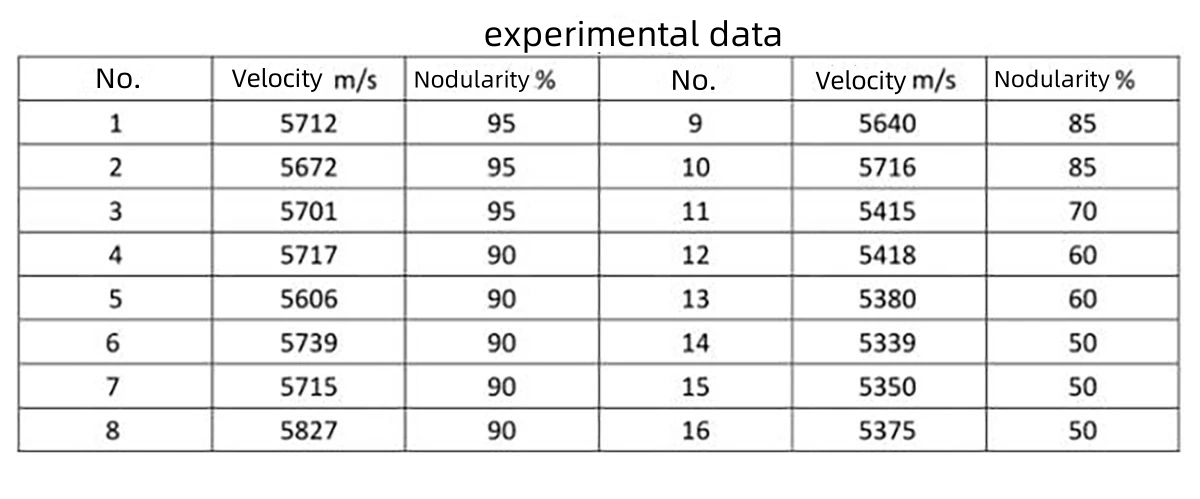

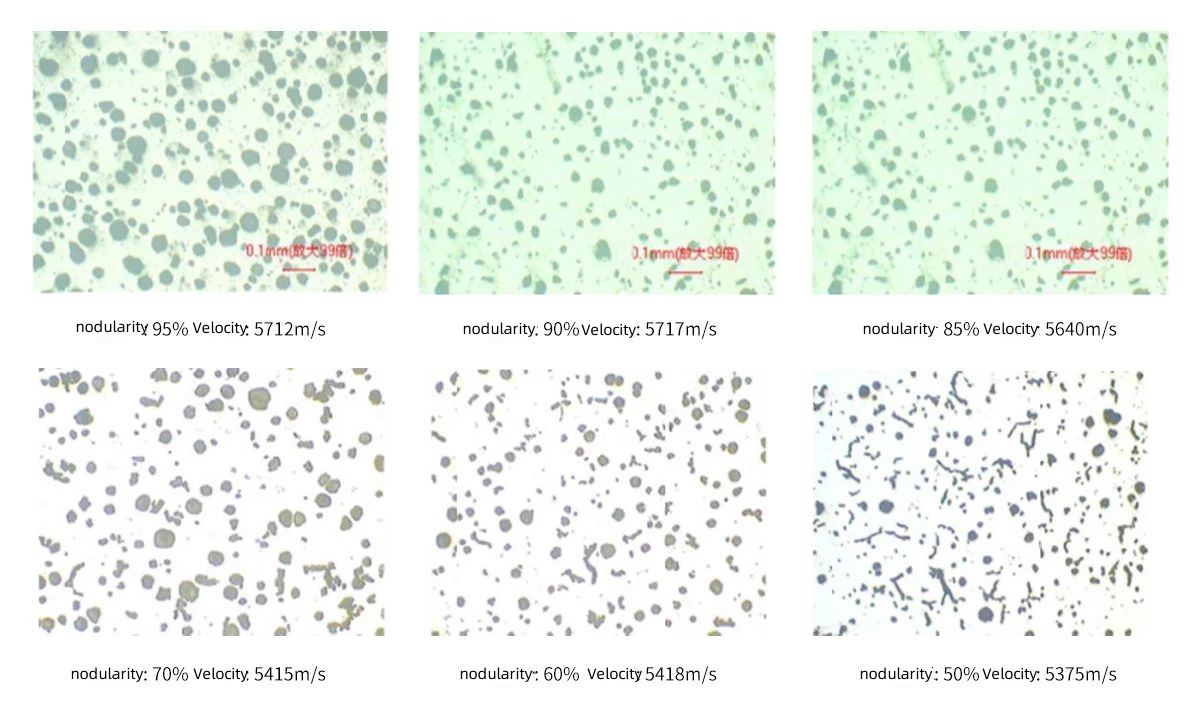

In order to verify the linear correspondence between nodular cast iron's spheroidized rate and sound velocity and whether the test results are stable and reliable, some professionals have respectively tested several parts and tested the spheroidized rate under a high-power computer microscope. The experimental records are shown in the following table, and the test metallography of some parts is shown in the following figure.

Conclusion: The comparison between sound velocity and metallographic spheroidization rate measured by sound tester can be concluded that the sound velocity value control greater than 5500m/s can ensure the spheroidization rate is greater than 80%.

Ultrasonic Testing

Although microscopic examination and tensile strength testing can effectively verify the spheroidized rate of cast iron, ultrasonic testing is the preferred method for rapid non-destructive evaluation of cast iron because of the different sound velocities of Nodular Cast iron and gray cast iron.

Nondestructive spheroidized rate testing can be done using an ultrasonic instrument capable of measuring the sound velocity of the material.

All models of YUSHI UM-4 series, UM-5 series and PM5 Gen2 of color display ultrasonic thickness gauges can perform specialized sound velocity measurements.

The PM5 Gen2 ultrasonic thickness gauge has a higher measurement update rate (up to 2KHz) than other ultrasonic thickness gauges. Measurement resolution of 0.001mm making sound velocity calculations more accurate. In addition, the PM5 Gen2 thickness gauge can be controlled by the upper computer through wireless or wired real-time communication options, real-time transmission of thickness values, waveforms, parameters, including the upper computer measurement software, this function has been widely used in actual production, is an ideal choice for online measurement and secondary development.

The sound velocity of pure iron, nodular cast iron and gray iron are different, and it is necessary to know the exact thickness of the sample to be measured when measuring the sound velocity. The operation of detecting spheroidized rate by ultrasonic need measuring its thickness with vernier calipers. If the thickness of the test location is unknown, an accurate sound velocity measurement cannot be completed.