The Principle and Method of Ultrasonic Thickness Measurement

Basic Principle

Ultrasonic thickness gauge measures the thickness based on the principle of ultrasonic pulse reflection. When the ultrasonic pulse emitted by the probe passes through the workpiece to be measured and reaches the material interface, the pulse is reflected back to the probe, and the thickness of the measured material is determined by accurately measuring the time of ultrasonic wave propagation in the material. This principle can be used to measure any material that can propagate ultrasonic waves at a constant speed within it.

H = v t / 2

H- Thickness; v- Sound Velocity; t-Measuring time;

Measuring Method

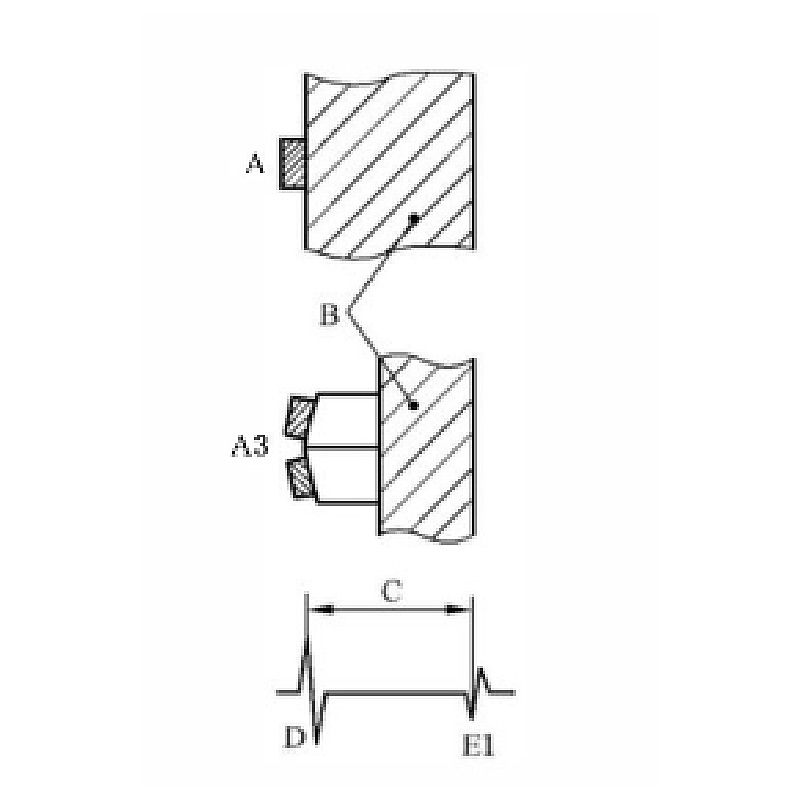

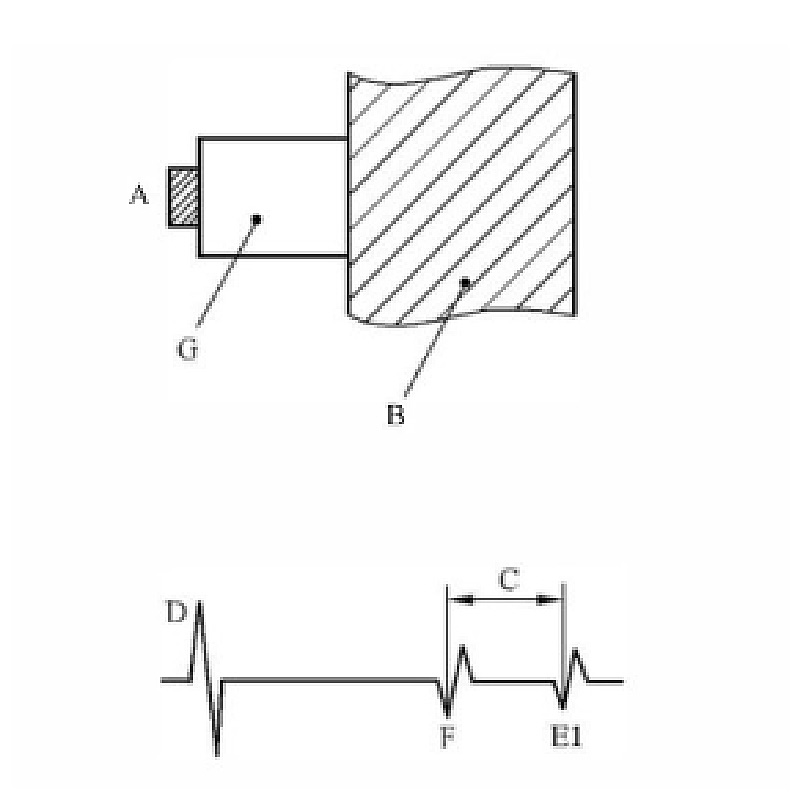

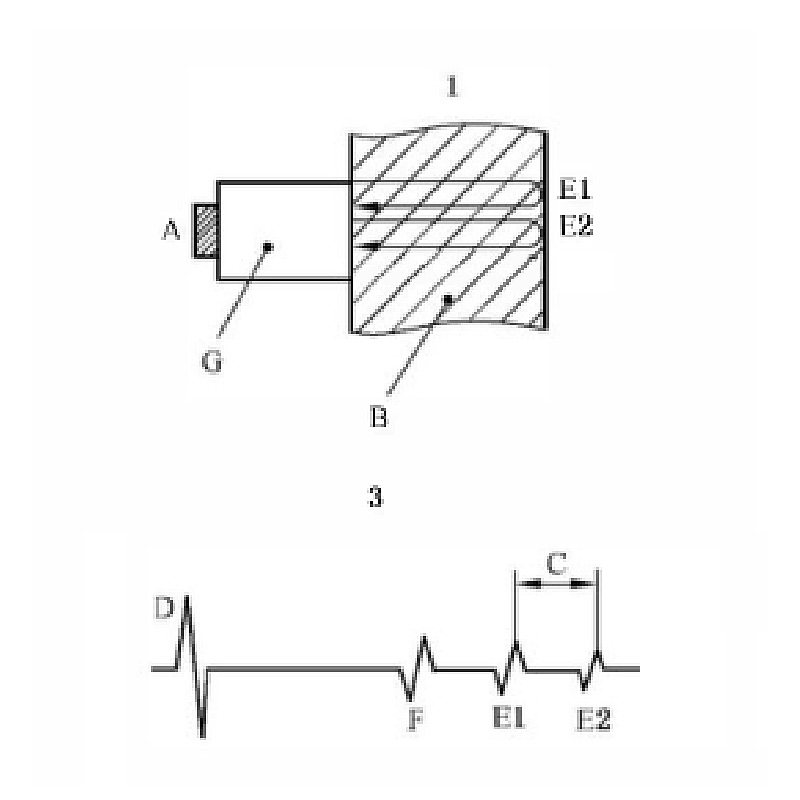

Index Number Description:

A-Transmit/Receive Probe;

A3-Double Element Probe

C-Ultrasonic Transmission Time;

D-Transmitting Pulse Signal

F-Interface Echo;

E1 E2-Bottom echo

G-Delay Path;B-Sample Under Test

P-E

Measure the time between the initial pulse and the first bottom echo, the zero point is corrected at the same time.

I-E

Measure the time between the delay line interface wave and the first bottom echo.

E-E

Measure the time between two consecutive bottom echoes.

Tips

★The appropriate thickness gauge and measurement method should be selected according to the material, geometry and thickness of the workpiece to be measured and the requirements of measurement accuracy. Accuracy of thickness measurement depends on the accuracy of ultrasonic travel time measurement.