Application of Ultrasonic Thickness Gauge in Quartz Crucible Thickness Measurement

Performance and Use of Quartz Crucible

Quartz crucible is a container made of quartz sand, with high purity, high temperature resistance, long service life and other properties. Quartz crucible is a necessary quartz container in the production of silicon single crystal and silicon polycrystalline of solar products, and is also the basic equipment of semiconductor industry and silicon solar cell.

Quartz crucible is a quartz device for holding silicon raw materials at high temperature (silicon liquid in a molten state during operation). It is an important consumable in the production of photovoltaic silicon wafers and is widely used in the photovoltaic and semiconductor silicon wafer production industries. In the field of scientific research, it is often used to study the melting properties of substances and prepare new materials; in the industrial field, it is widely used in metallurgy, ceramics, glass and electronics,etc.

Sample

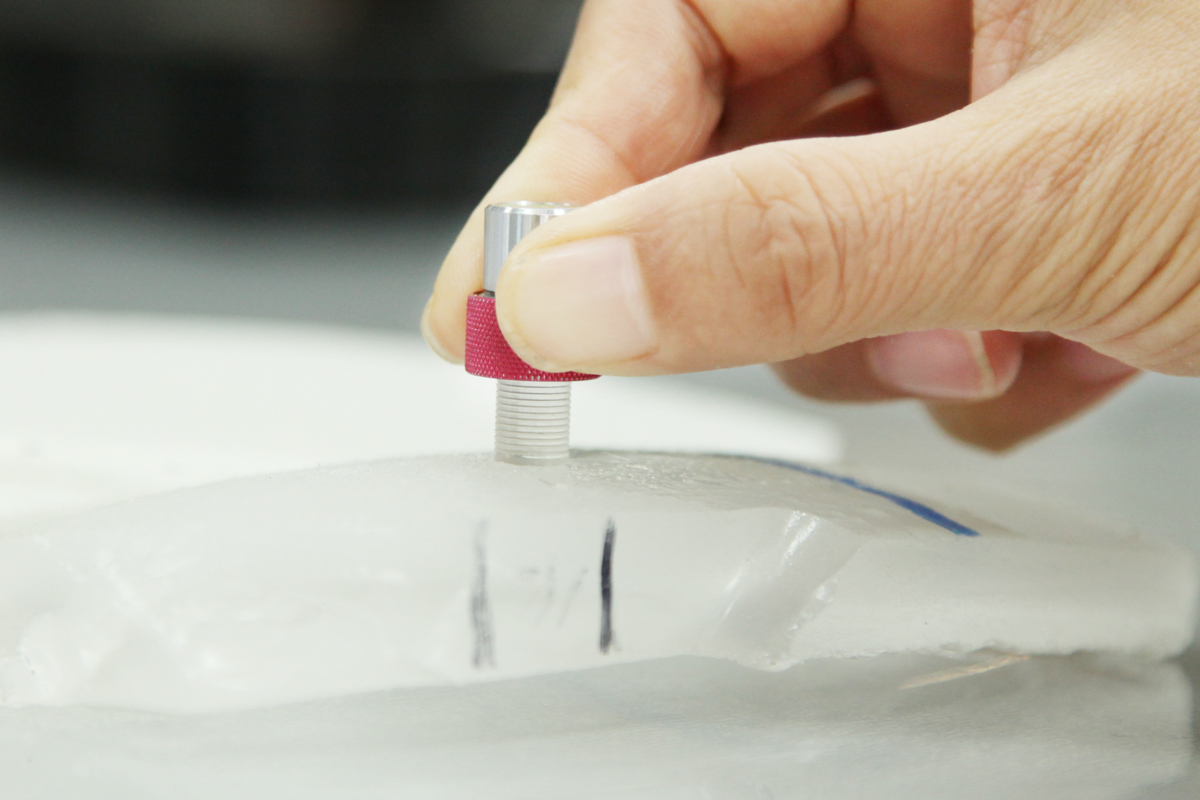

We received the sample from our customer, quartz crucible material with thickness of about 20 mm, and need to measure its thickness.

In the production of silicon single crystals and silicon polycrystals, quartz crucibles is used as carrier for melting high-purity silicon. In order to ensure product quality, the inspection of quartz crucible is a very key stage. Measuring its thickness is also one of the inspection items, and it needs to meet on-site inspection.

Measurement Analysis

Use of portable ultrasonic thickness gauge is much more convenient than laboratory testing equipment. It can test the thickness of quartz crucible anytime and anywhere and store the measurement results, which makes up for the shortcomings of quartz crucible laboratory testing.

Instrument and probe selection:

When measuring, it’s important to consider the thickness, shape, material and other factors of the workpiece being measured and select the appropriate ultrasonic thickness gauge and probe, which is very important for the measurement results.

The customer couldn’t measure the thickness with an ordinary ultrasonic thickness gauge. And we use YUSHI PM5 Gen2 ultrasonic thickness gauge to get the correct measurement by adjusting A-scan waveform. In addition, the selection of a suitable probe is also very important, the crucible container with curvature needs to choose a small contact surface probe to ensure the probe and the material are fully coupled. We use our D5A6 delay line probe and get stable measurement values, clear echoes and accurate results.

Measuring Result

As the only material in direct contact with silicon solution, quartz crucible plays an important role in scientific research and industry. If you want to learn more about the method of measuring the thickness of quartz crucible using ultrasonic technology, or any measurement problems, please feel free to contact us. We will help to make solution according to your needs.