How to Detect Pitting Corrosion in Advance When Inspecting Industrial Pipe Wall Thickness

Importance of Testing

Pitting is the initial stage of corrosion damage. It is a form of corrosion damage in which the metal surface is directly exposed to the corrosive environment to form local corrosion holes and develop in depth due to the destruction of the protective layer and local penetration under the action of tensile stress or chemical substances. Fatigue sources are usually easily formed in the pitting area. Pitting forms corrosion pits on the surface of the structure and changes the surface state of the structure, leading to local or comprehensive damage.

When metal material structure is affected by the medium, its state changes to form a new phase, resulting in corrosion damage, which is very harmful to national defense construction and may lead to major or even catastrophic consequences. Countries around the world invest a lot of manpower and material resources in corrosion detection and protection every year. Corrosion detection has become one of the important fields of modern science and technology research.

Industry | introduction

In order to evaluate the degree of wall thickness reduction during use and infer the wall thickness reduction speed, industries such as petroleum, chemical, natural gas pipeline, boiler pressure vessel, etc. need to use ultrasonic thickness gauge to measure the remaining wall thickness of the pipeline to estimate the remaining life of the pipeline. We can predict and intervene in the pitting corrosion that may occur in advance when the pipeline is not seriously corroded, which will extend the service life of the pipeline.

Test Block

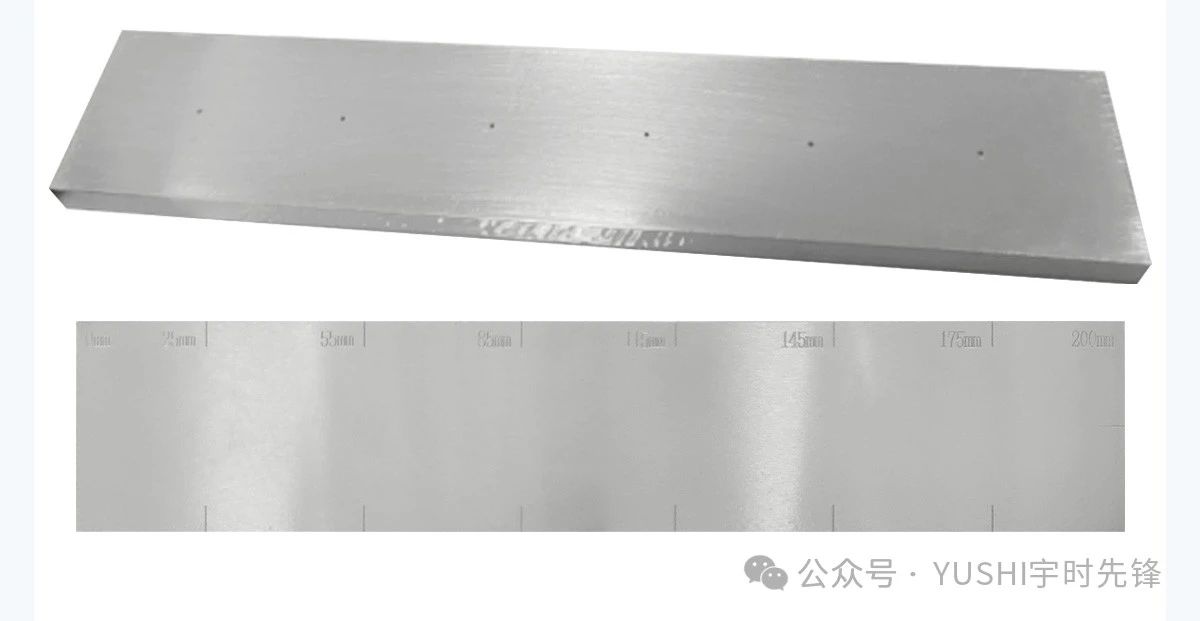

We have received a request from an oil company about whether pitting defects with a diameter of more than 1mm can be detected in advance when measuring the wall thickness of oil pipeline. In response to this requirement, we specified a pitting comparison test block with an actual wall thickness of 8mm. 6 artificial defects with a diameter of 1mm are made at the bottom of the block. The bottom pattern of the test block is as follows: The depths of the artificial defects from left to right to the upper surface of the test block are: 6.9, 6.1, 5.1, 3.9, 3.1, and 2.1 mm.

Measurement

1. Without Defects

Using ultrasonic instruments to detect small-diameter point defects and accurately identify them requires extremely high detection resolution and instrument accuracy, and the instrument needs to have real-time A-scan function to clearly display the pulse wave of the defect. We use PM5 Gen2 ultrasonic thickness gauge with A-scan real-time waveform display to test on the front of the test block. When measuring the area without defects, in addition to the interface reflection wave, only the bottom reflection waveform of the sample block is obtained.

2. With Defects

When the probe is placed directly above the artificial defect, it can be seen from the waveform that there is a set of defect reflection waveforms in front of the bottom surface reflection wave of the sample block, and the depth and position of the defect wave are displayed. The waveform with a red circle in the figure below is the defect reflection wave.

Summarize

Through the above tests, our YUSHI ultrasonic thickness gauge can distinguish pitting defects with a diameter of 1mm. For the wall thickness detection of oil and natural gas pipelines, it not only measures the wall thickness, but also helps you to discover small pitting defects that may exist in the pipeline in advance, which is very beneficial for predicting corrosion defects in advance.