Coating Thickness Gauge Purchase Tips and Product Recommendation

Coating thickness gauge is used for measuring the coating thickness on the surface of metal substrates. The measurement principle determines that different instruments are needed to test the coating thickness of different metal substrates. When purchasing, it’s necessary to consider the actual test material, coating thickness, application fields, product performance, and manufacturer service and other aspects. This article summarizes several tips for purchasing coating thickness gauges and recommends high-quality instruments.

Select According to the Test Material

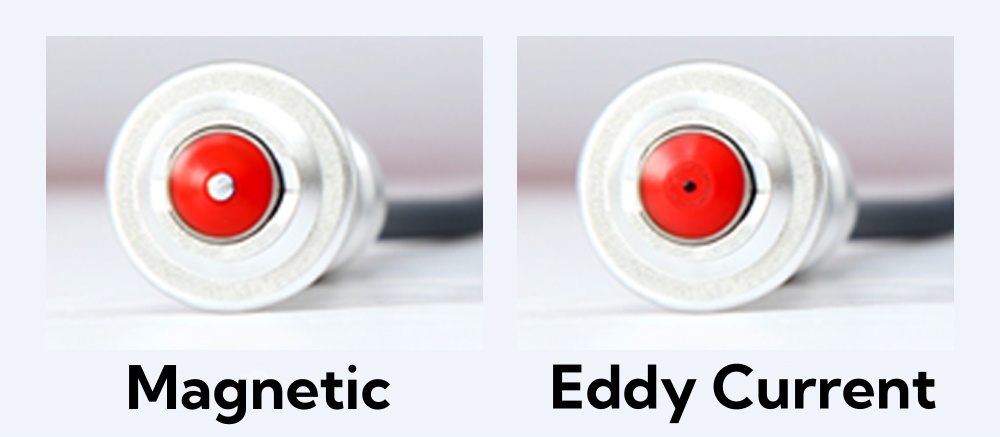

Coating thickness gauges are divided into two types according to the measurement principle: magnetic method and eddy current method.

Magnetic Method (Fe): Measuring the thickness of non- magnetic coatings on steel, iron and other ferromagnetic metal substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, phosphate coating, chromium, zinc, Aluminum, tin and cadmium, etc.

Eddy Current Method (NFe): measuring the thickness of non-conductive coatings on copper, aluminum, stainless steel and other non-ferromagnetic substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, oxide film and phosphate film, etc.

Select According to the Measurement Range

Select the coating thickness gauge with the appropriate measuring range according to the coating thickness on the metal surface. The general paint coating is relatively thin, and the instrument with a measuring range of 0-1500μm can be selected. However, if you want to measure fire retardant coatings or anti-corrosion coatings, it is recommended to purchase a coating thickness gauge with a large measuring range, such as YUSHI CM10FH. It’s large-range with the probe measuring range up to 10000μm, which is very suitable for measuring thick coatings.

Product Performance

The performance of the coating thickness gauge determines the failure rate and service life we use, which will affect the work efficiency and data reliability.Mainly includes product function, operating temperature, measuring range, reading accuracy, measurement parameters, etc. in the selection must ensure that these points meet the application requirements of the product.

YUSHI CM30 coating thickness gauge is a full-range, multi-functional coating thickness gauge developed on the basis of CM10 series. It can be equipped with separate probes, users can choose one or more probes according to their needs. 2.4-inch color LCD display, 200,000 measurement values storage, and has passed IP68 waterproof and dustproof test.

Manufacturer Service and Technical Support

The purchase of coating thickness gauge must choose a regular manufacturer, which represents the manufacturer's service guarantee. It is not only pre-sales service, but also after-sale service includes professional technical service and maintenance service during the using.

YUSHI INSTRUMENTS has been committed to the R&D, production and sales of non-destructive testing instruments for many years, providing customers with professional technical support and services. If you have related product needs and any technical questions, please feel free to contact us at any time.