Ultrasonic Thickness Gauge Application In Measuring the Wall Thickness of Light Bulbs, Tubes and Lamps

Light Bulb Application

We use light bulbs every day. As part of our lives, the most common application of light bulbs is lighting. But with the progress of society, there have been significant changes in the use of light bulbs. Functional lights for different purposes such as "photography, signs, cars, beautify the environment", etc. Light bulbs have a wide range of applications, whether providing basic lighting functions or being used in the fields of creativity and technology.

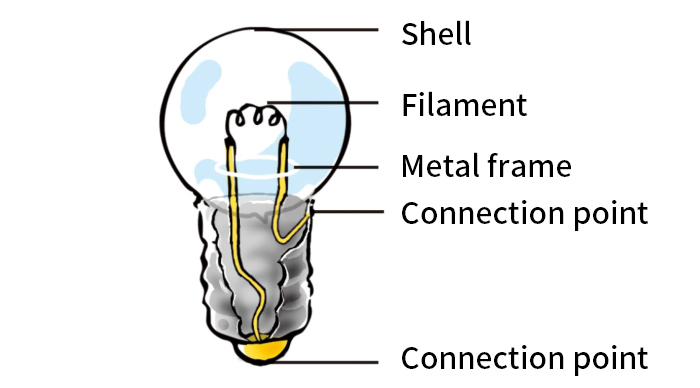

Composition of Light Bulb

The light bulb is mainly composed of filament, shell, light head and other parts. The materials of the light bulb shell mainly include glass, plastic and ceramic. The material of the light bulb is an important factor affecting its performance. Different materials have their own advantages and disadvantages. Light bulb manufacturers select the appropriate material for production according to actual needs. There are also certain requirements for the wall thickness of the light bulb during the production process to ensure the product is beautiful, practical, firm and safe.

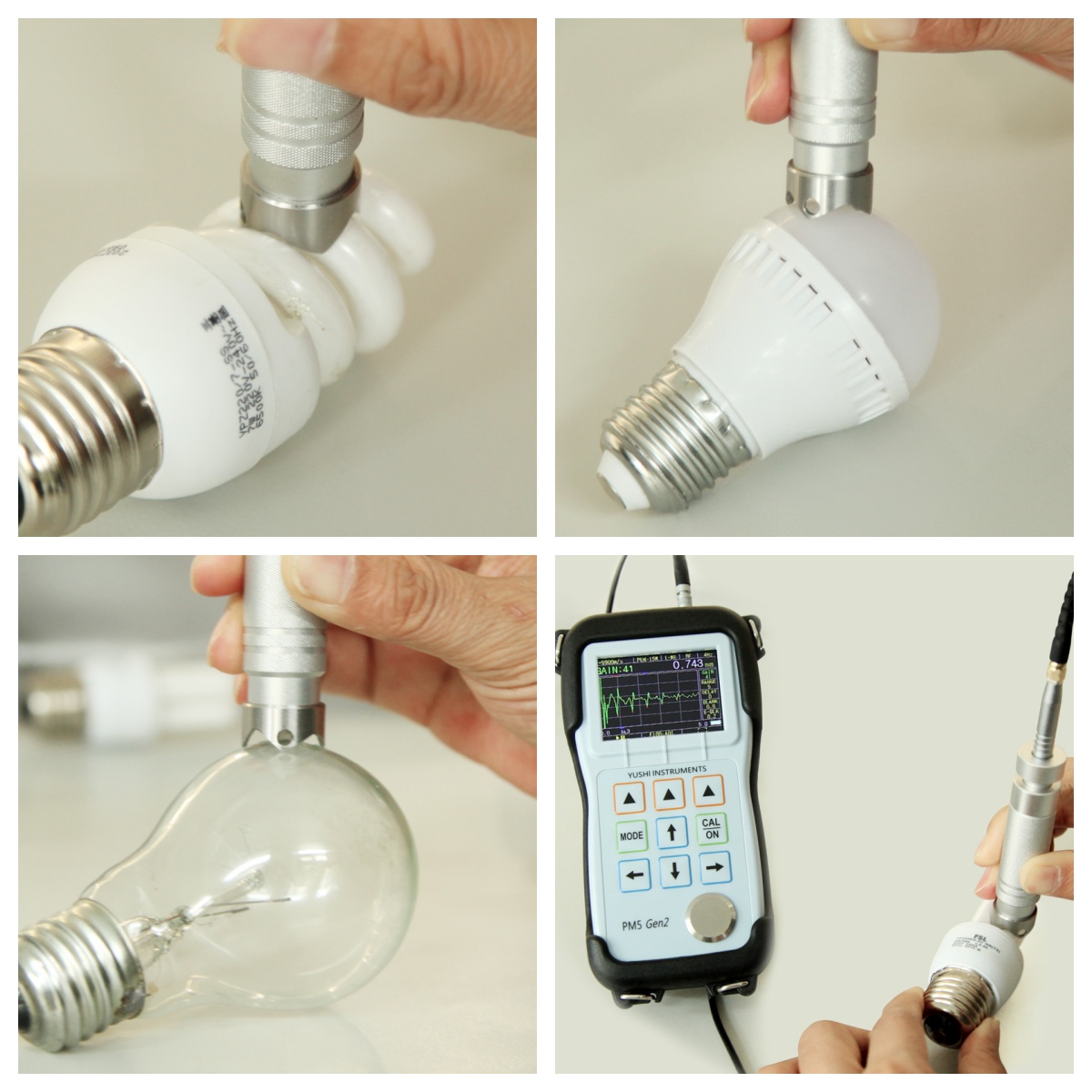

Product Sample

We received product samples from customers, material is glass and plastic. The shapes include bubbles, tubes and spiral tubes. thickness range 0.3mm-1mm. The customer requires measure its thickness and uniformity.

Measuring Analysis

The sample we received was a closed bulb, so it was impossible to measure with a caliper or micrometer. The main advantage of ultrasonic thickness measurement is that it is possible to measure the thickness of closed containers and other complex shaped samples that are difficult or impossible to reach both sides of the material. This method only needs to contact one side of the workpiece to measure the thickness.

When measuring, considering that the shape of the workpiece is a bubble or tube with curvature, it’s necessary to select a small contact surface probe, probe with large contact surface can’t fully contact such a small measuring surface, and the echo is unstable, some parts can not even get the bottom echo, and the measurement can not be achieved.

Measuring Result

We use YUSHI PM5 Gen2 ultrasonic thickness gauge with the standard probe or a pencil delay line probe to measure (depending on the curvature of the measuring surface). When the narrow tip end of the pencil probe is perpendicular to the surface of the measured material, the echo signal is the largest and the measured value is the most stable. At this time we need to use a test holder to test, which ensures stable and accurate measurement, clear echo, and good repeatability. Directional capture or automatic freezing can also be selected to make measurements easier and faster.

Ultrasonic thickness gauges can be used to measure all common glass, plastic and ceramic products, including bottles, containers, pipes, plates, etc. For some complex geometric shapes or other special shaped workpieces, we recommend the water immersion method for measurement. If you have the same measurement requirements in your application, or have problems in your measurement, please feel free to contact us and we will provide you with best solutions.