Application of Ultrasonic Thickness Gauge in Thickness Measurement of Aluminum Copper Composite Plate

The Introduction of Copper-Aluminum Composite Plate

Copper-aluminum composite plate is a new material in which copper plates and aluminum plates are welded together through cold rolling, hot rolling, explosive composite method, explosion rolling method, etc. and cannot be separated. We all know that replacing copper with aluminum can not only save costs, but also achieve the development policy of energy conservation and emission reduction. Copper-aluminum composite boards are widely used in industry, especially in the power industry.

Advantages and Applications of Copper-Aluminum Composite Plate

The specific gravity of copper-aluminum composite plate is smaller than that of pure copper, which can replace pure copper to save cost and light body area.

Under high temperature, high pressure, and oxygen free conditions, the research and development of technology fusion casting and continuous composite production solve the problems of oxidation and eutectic between the transition layers of two metals, ensuring the bonding strength and bonding rate between the two metals.

Copper aluminum radiators used for hot water heating have advantages such as good thermal conductivity, high pressure resistance, and strong corrosion resistance.

It has the advantages of low thermal resistance, good heat dissipation, easy mechanical processing, and good electromagnetic shielding, and widely used in printed circuit boards in industries such as automobiles, motorcycles, televisions, and electronic components.

Copper aluminum composite plate used as a conductive plate for power supply and a transition joint for copper aluminum busbar. The surface will not overheat or arc, ensuring stable conductivity, reducing electrical energy loss, and extending the service life of the conductive plate.

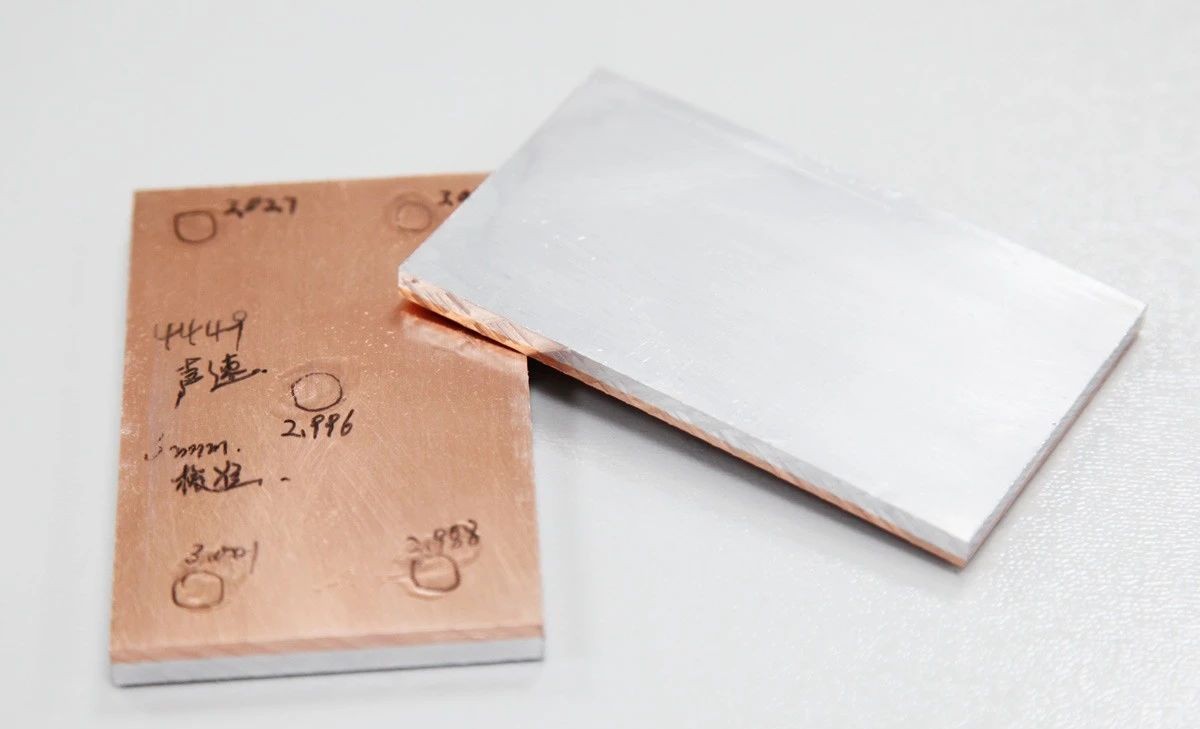

Product Samples and Customer Requirements

We received product samples from the manufacturer of copper aluminum composite plates, which are made of copper aluminum composite plates. Customer requests to measure the thickness of copper material, with thickness of 0.2-5.0mm, display resolution of 0.001mm, and accuracy error of ± 0.02mm.

Ultrasonic Thickness Gauge and Probe Selection

YUSHI PM5 Gen2 precision ultrasonic thickness gauge with measurement resolution of 0.001mm. We use a 15M single crystal delay line probe for measurement, which has good repeatability and stability, clear echoes, and more accurate measurement values.

Our PM5 Gen2 thickness gauge can also perform dual-layer measurements, displaying 2 layers of material thickness simultaneously.

PM5 Gen2 portable thickness gauge can meet most measurement needs using single crystal probes of different frequencies and types. Moreover, the measurement range is wide, ranging from 0.15mm thick thin steel plates to tens of meters long steel bars, and even tens of micrometers of thin paint layers, all of which can be measured. The fully functional PM5 Gen2 is an innovative measuring instrument that integrates multiple solutions and can be effectively applied to most thickness measurement applications.

If you want to learn about using ultrasonic technology to measure metal composite materials, or encounter problems in measurement applications, please contact us for sample testing to provide you with a thickness measurement solution.