Relationship between Gain and Temperature in High Temperature Measurement

Application of high temperature thickness gauge

High temperature ultrasonic thickness gauge is a testing instrument used to measure the residual thickness of high-temperature materials. It is widely used in fields such as petrochemicals, natural gas, nuclear power, offshore platforms, ships, etc. It plays a significant role in thickness measurement of internal corrosion and thinning in high-temperature media. However, the detection results of high-temperature thickness gauges are influenced by various factors, including environmental factors, equipment factors, and so on. The factors of the high-temperature thickness gauge itself can also affect the measurement results. For example, factors such as instrument accuracy, sensitivity (gain), stability, etc. will all affect the accuracy of measurements.

Gain means amplification, and the signal is processed through an amplifier based on different gain values (i.e. amplification multiples). A large gain results in a large signal value, which is equivalent to a high A-scan echo amplitude displayed on the screen for an ultrasonic thickness gauge.

We tested the relationship between gain value and temperature in high-temperature measurement, recording and analyzing the changes in gain value under different thicknesses and temperatures.

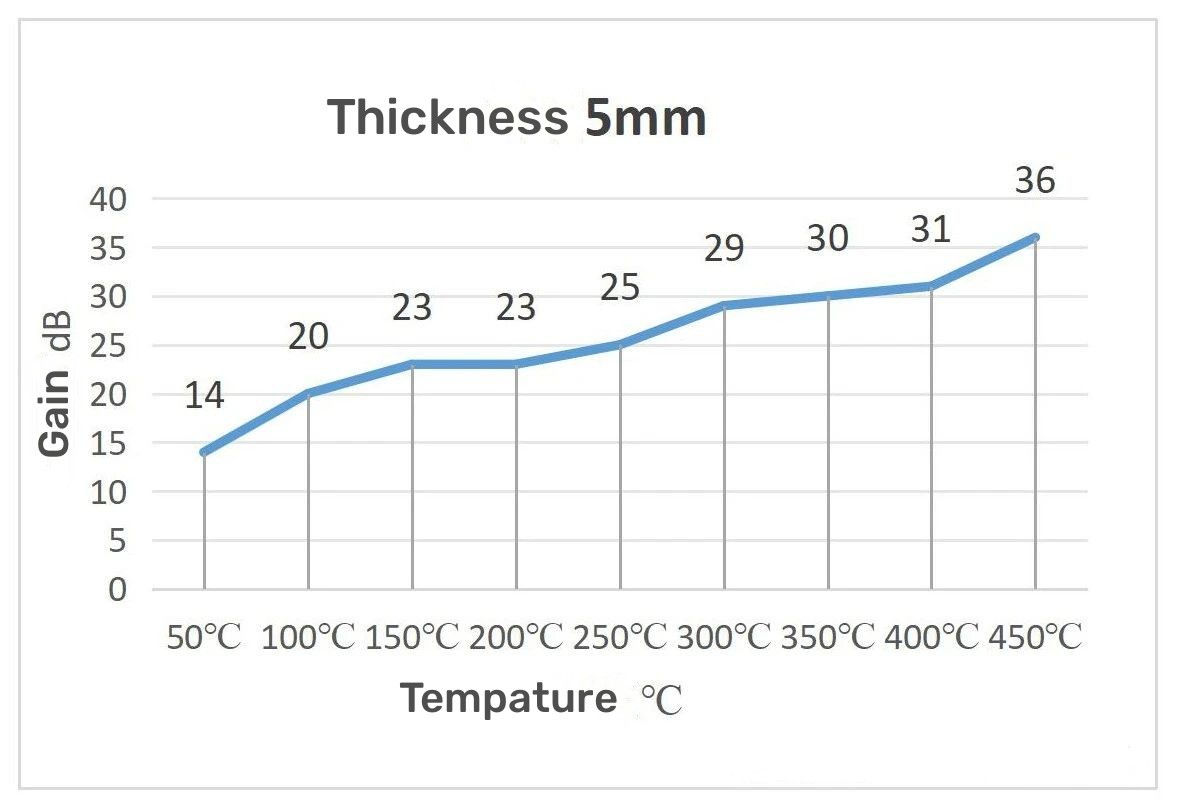

Figure 1

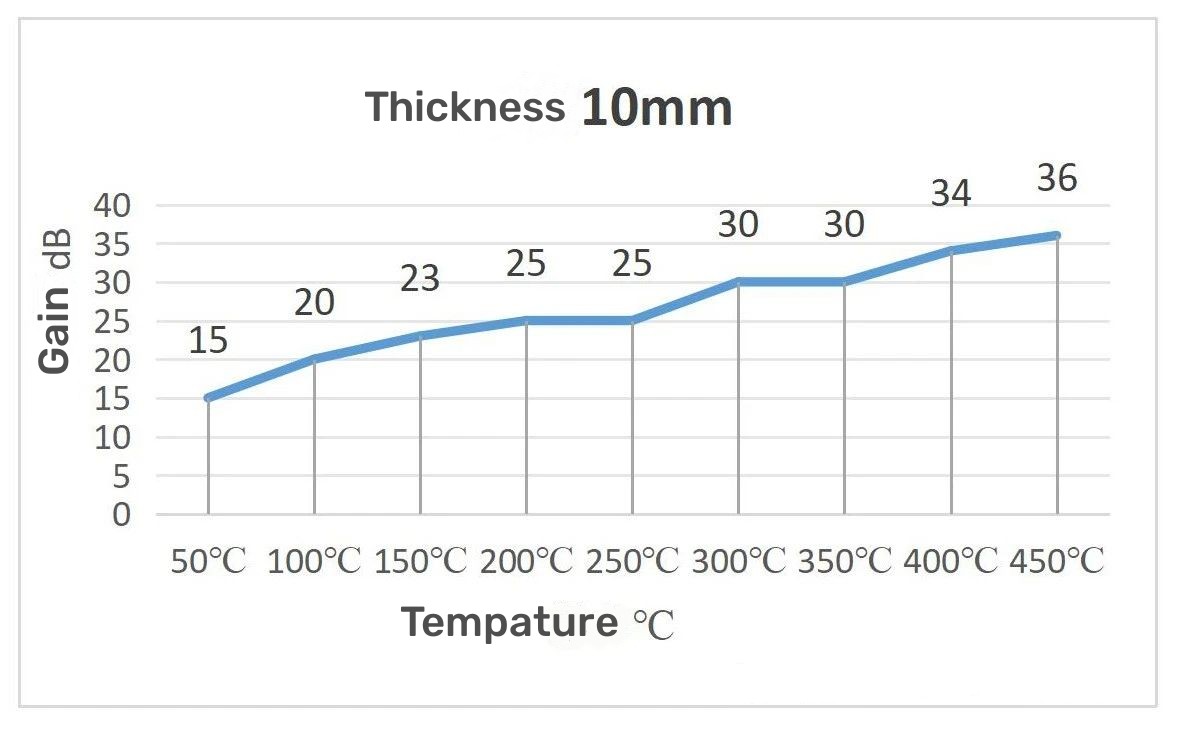

Figure 2

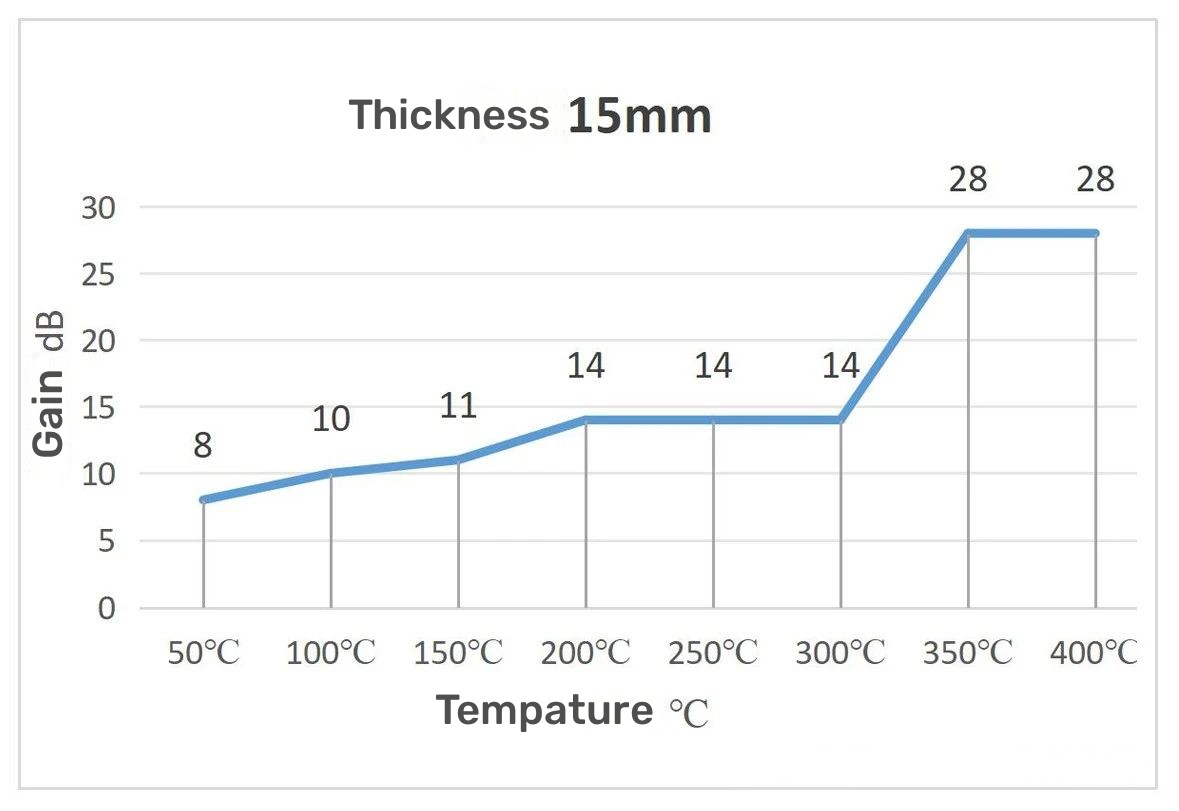

Figure 3

Test Result

As shown in Figure 1, as the temperature of the measured workpiece increases, the gain value of the instrument needs to increase. From 50 ℃ to 450 ℃, the gain value increases by 22dB. The higher the temperature, the higher the gain value required for the tested workpiece.

In high temperature thickness measurement, the gain value of the instrument is too low, which will cause the measurement instability or even no measurement value, so it is very important to choose the appropriate gain value. The Yushi Pioneer PM5 Gen2 thickness gauge with high measurement sensitivity. At the same time, it has the functions of high temperature compensation and gain adjustment to ensure the accuracy and reliability of the measurement results.