Advantage and Application of Ultrasonic Immersion Thickness Measurement

Water immersion thickness measurement is a method of ultrasonic thickness measurement, which is characterized by using water as a couplant for the workpiece and probe. During testing, the workpiece and the probe are put into the water together, and the probe is at a certain distance from the workpiece (called the water layer thickness).

After the ultrasonic wave is emitted, it passes through the water to the surface of the workpiece and then transfers into the interior of the workpiece. The thickness of the workpiece can be correctly displayed by adjusting the A-scan waveform on the display.

Principle of water immersion thickness measurement

Ultrasonic thickness gauge is based on the principle of ultrasonic pulse reflection to measure the thickness of the measured material. When the ultrasonic pulse emitted by the probe reaches the material interface through the measured object, the pulse is reflected back to the probe, and the thickness of the measured material is determined by accurately measuring the time that the ultrasonic wave travels through the material.

The ultrasonic water immersion thickness measurement method is to place the probe in water, and its emission of ultrasonic waves will generate multiple water interface reflection waves. At the same time, the tested object will also generate reflection waves.

Due to the different velocity of ultrasonic waves in water and the tested material, by adjusting the thickness of the water layer between the probe and the object being tested, the bottom wave of the object being tested is positioned in front of the reflected wave at the second water interface.

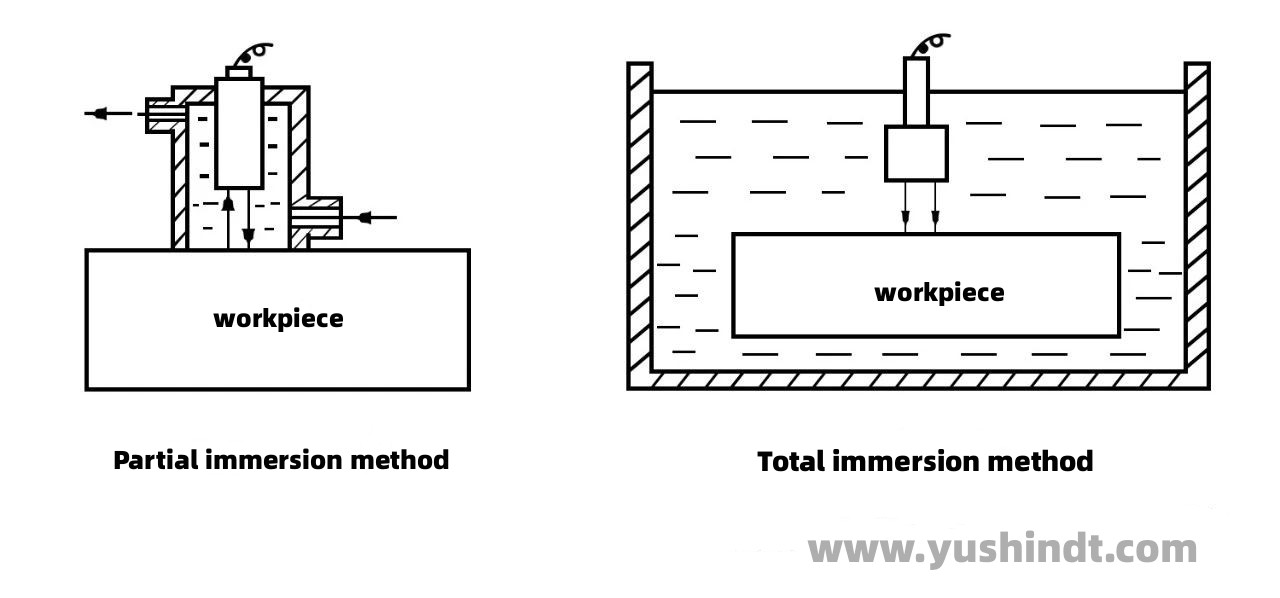

Classification by water immersion

The water immersion thickness measurement is generally divided into two methods: partial water immersion method and total water immersion method.

Partial water immersion uses the water-filled probe and is mainly used to replace large-area thickness measurement to improve work efficiency; Total water immersion uses the water immersion probe and is suitable for rough surfaces, Automatic measurement of workpieces with complex shapes and poor coupling conditions, such as pipes and bars.

Application

We received sample filter material from customers (diameter 30-40mm, wall thickness 5-9mm or so), the filter is sintered by high temperature and high pressure, and there are micro-pore distribution. The customer requires measuring its wall thickness, testing its uniformity and minimum thickness.

Measuring Results

Due to the special structure of this material, the conventional ultrasonic thickness measurement method is difficult to receive the bottom echo and can not be measured. After the test, Using YUSHI PM-5 series ultrasonic thickness gauge for water immersion testing, the echo is clear, and the measurement value is fast, stable and accurate.

Summarize

Summarize

In the daily ultrasonic measurement, some workpiece due to rough surface, irregular shape and other special reasons, cannot be measured by contact method. For such workpieces, it is advisable to try to use water immersion ultrasonic thickness measurement.

If the ordinary probe is used as a water immersion probe, the acoustic beam diffusion will increase after the sound wave enters the workpiece, and the ultrasonic ability will be weakened after the sound energy passes through the water layer and diffuses in the workpiece, resulting in reduced detection sensitivity. In order to concentrate sound energy, the focusing probe should be used, and the probe frequency is selected according to the characteristics of the material.

Water immersion thickness measurement has high sensitivity, liquid coupling reduces sound energy loss, and water immersion thickness measurement can overcome the sound energy loss caused by rough workpiece surface or surface shape.

Because no close contact is required, the measurement speed is improved, and it is suitable for the secondary development of online measurement.