Fiberglass Thickness Measurement On Pipe Inner Wall

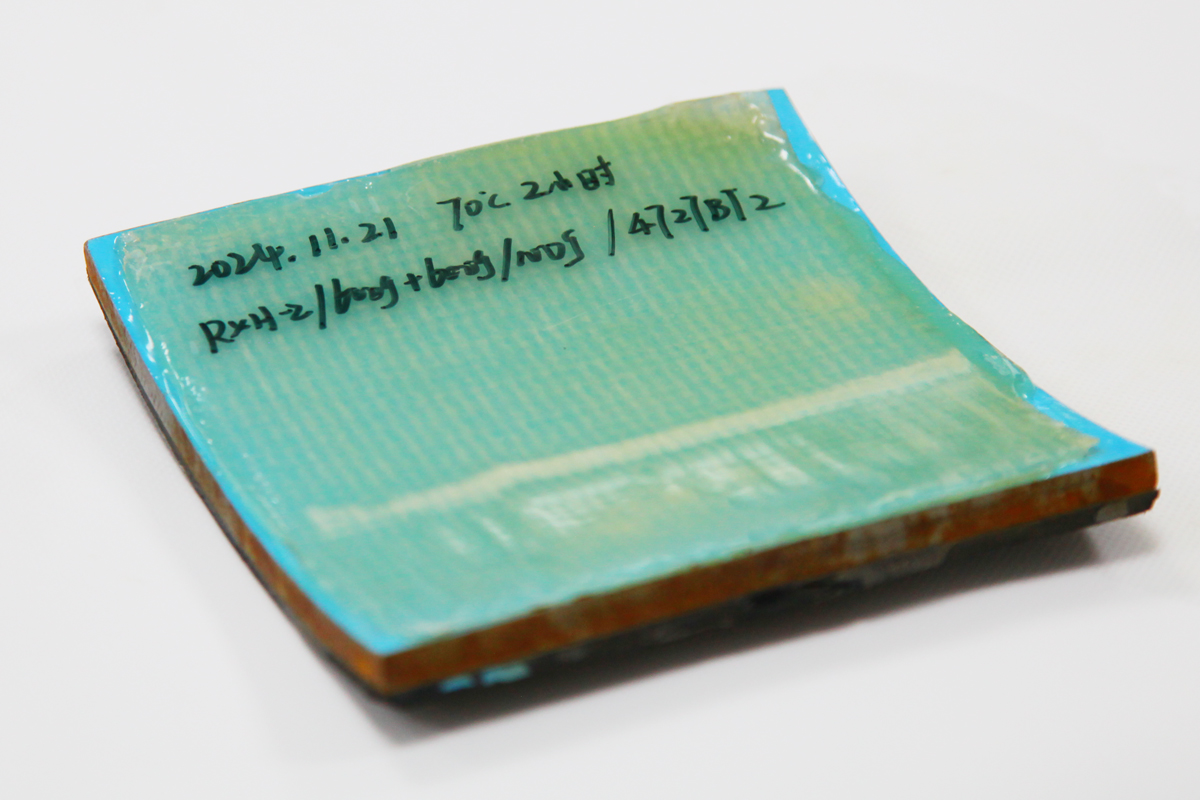

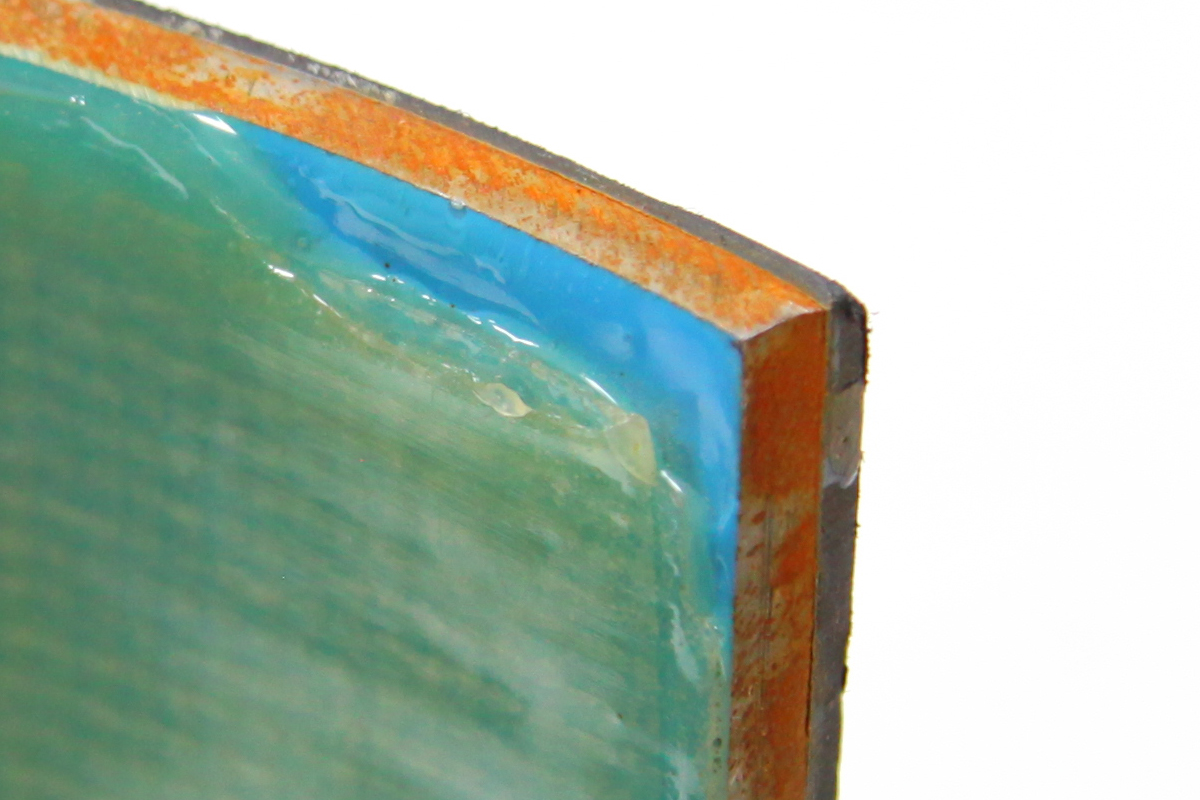

Test Sample

The test sample we received from our customer is taken from a section of a pipe, the pipe is made of three layers of material, the innermost layer of fiberglass is what the customer want us to measure accurately.

Material Introduction

Fiberglass reinforced plastic (FRP) has excellent corrosion resistance, high strength and light weight, making it an ideal choice for pipe linings in many industrial fields. Through advanced composite technology, fiberglass can fit tightly to the inner wall of the pipe to form a solid and smooth protective layer, effectively resisting the challenges of chemical erosion, water erosion, high temperature / pressure and other harsh environments. In addition, its good insulation properties can also help reduce energy loss and improve the overall energy efficiency of the pipeline system. The application of fiberglass materials not only extends the service life of the pipeline and reduces maintenance costs, but also improves the safety and efficiency of fluid transmission. It is an indispensable innovative material in modern pipeline engineering.

In order to ensure the safety of the pipeline system, it is important to check its inner wall thickness regularly. When conducting such inspections, using an ultrasonic thickness gauge to measure the inner wall of the fiberglass is an extremely efficient and accurate method. Ultrasonic thickness measurement not only won’t cause any damage to the pipeline material, but also covers a wider inspection area to ensure that every detail is fully evaluated, so that workers can find and deal with safety hazards in time.

Measuring Instrument

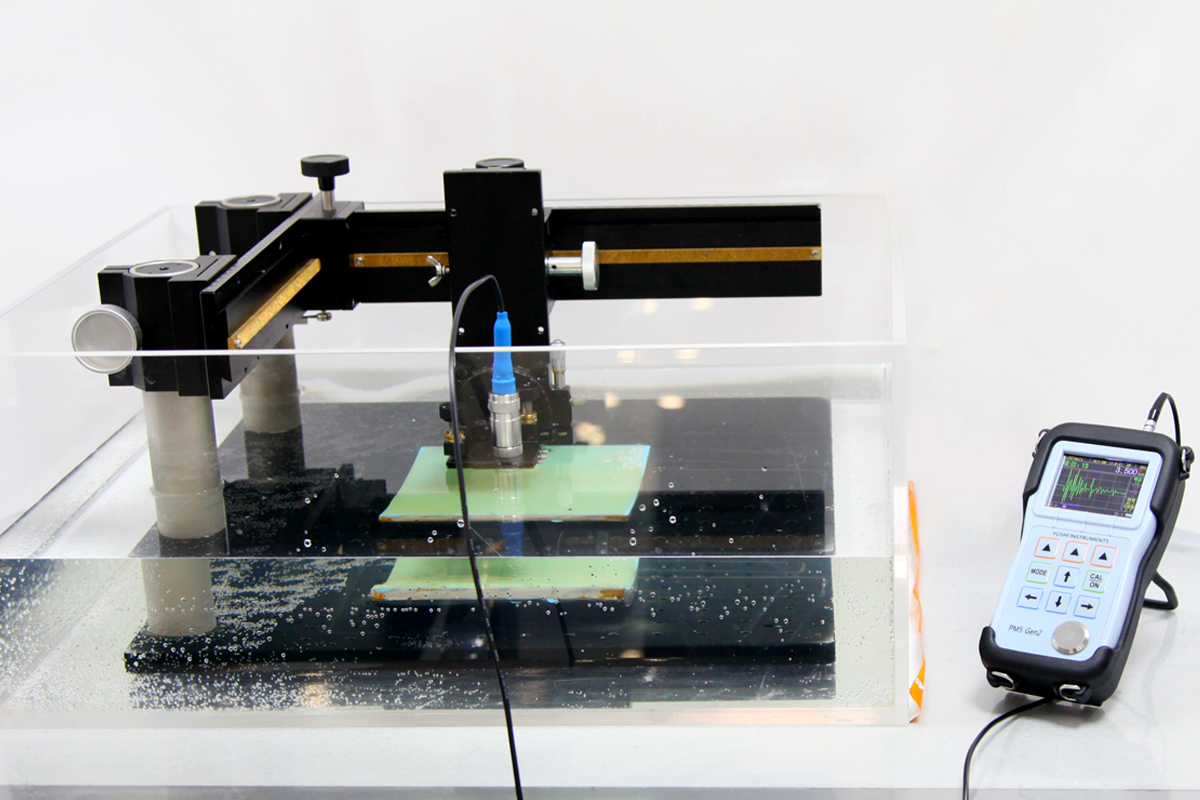

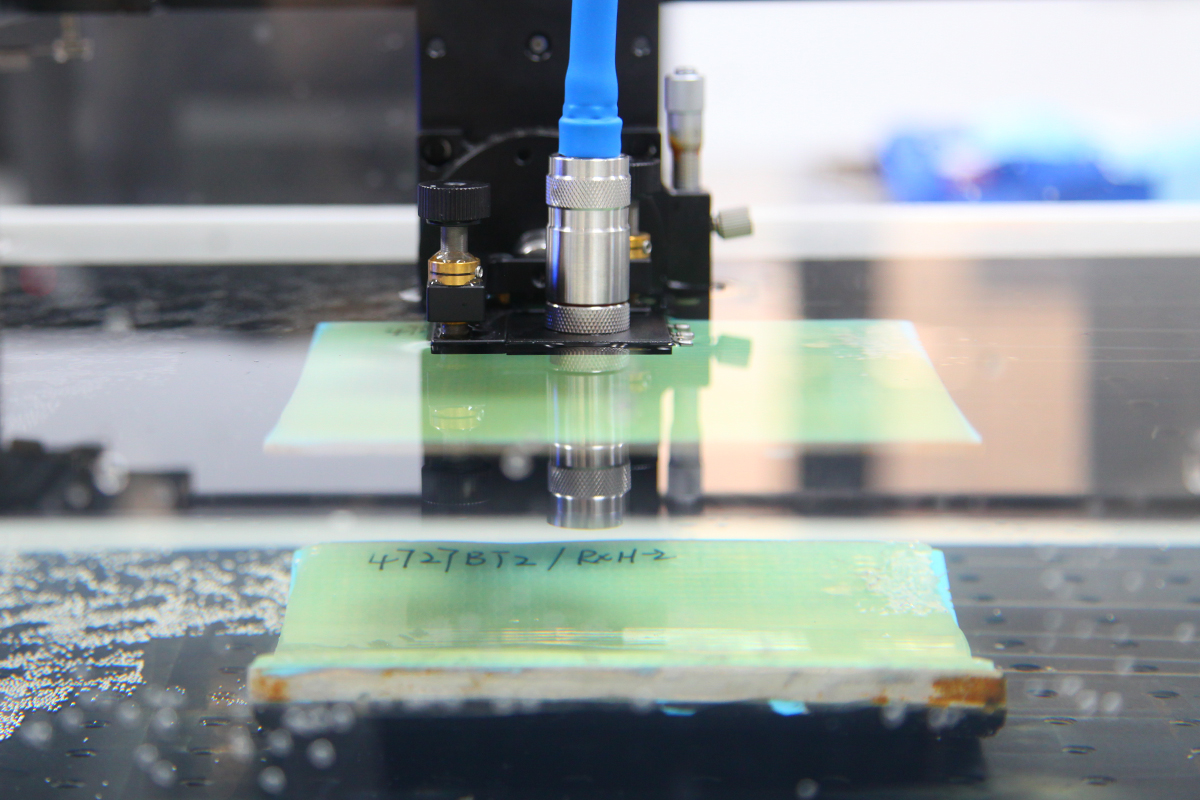

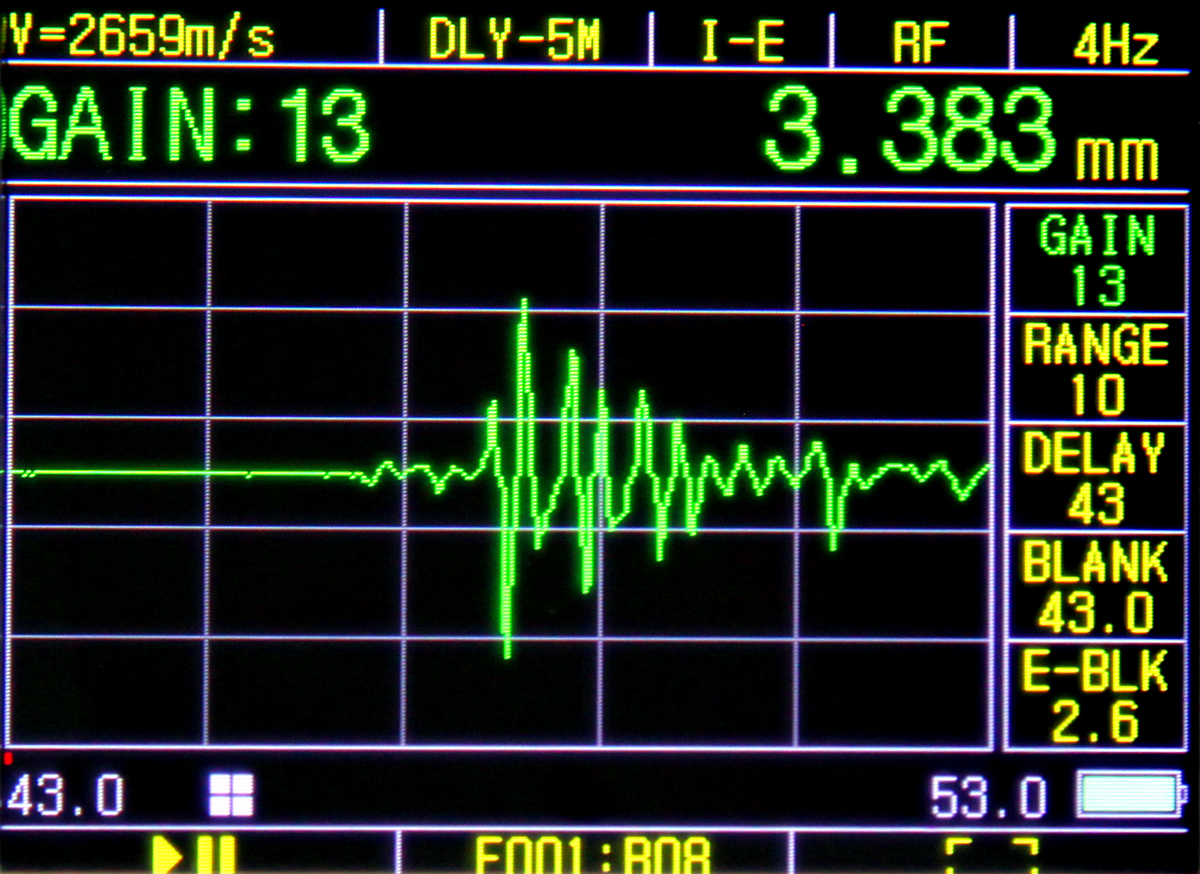

YUSHI PM5 Gen2 ultrasonic thickness gauge can well measure the fiberglass thickness on the inner wall of pipes.

Fiberglass laminate often has a multi-layer structure, interface between layer and layer may produce reflection and interference, which is difficult to measure. Therefore, we choose to use 5M immersion probe. On the premise of ensuring that ultrasonic waves can effectively penetrate glass fibers, it can combine the efficiency and operational flexibility of water immersion thickness measurement technology.

Measuring Method Introduction - Water Immersion Method

Ultrasonic water immersion thickness measurement technology effectively shields the interference of air on ultrasonic propagation through the medium of water, ensuring the stability and clarity of the measurement signal, thereby significantly improving the accuracy and reliability of the measurement.

In industrial applications, water as a highly efficient couplant, not only ensures the continuous operation of ultrasonic thickness measurement, but also realizes the recycling of resources, which is in line with the concept of green testing.

Ultrasonic water immersion thickness measurement technology can easily meet the measurement needs of various shapes and materials, especially for large areas or hard-to-reach areas. this technology has shown irreplaceable advantages.

Measuring Point

When using PM5 Gen2 ultrasonic thickness gauge for water immersion thickness measurement, two key points need to be noted to ensure the accuracy and reliability of the measurement.

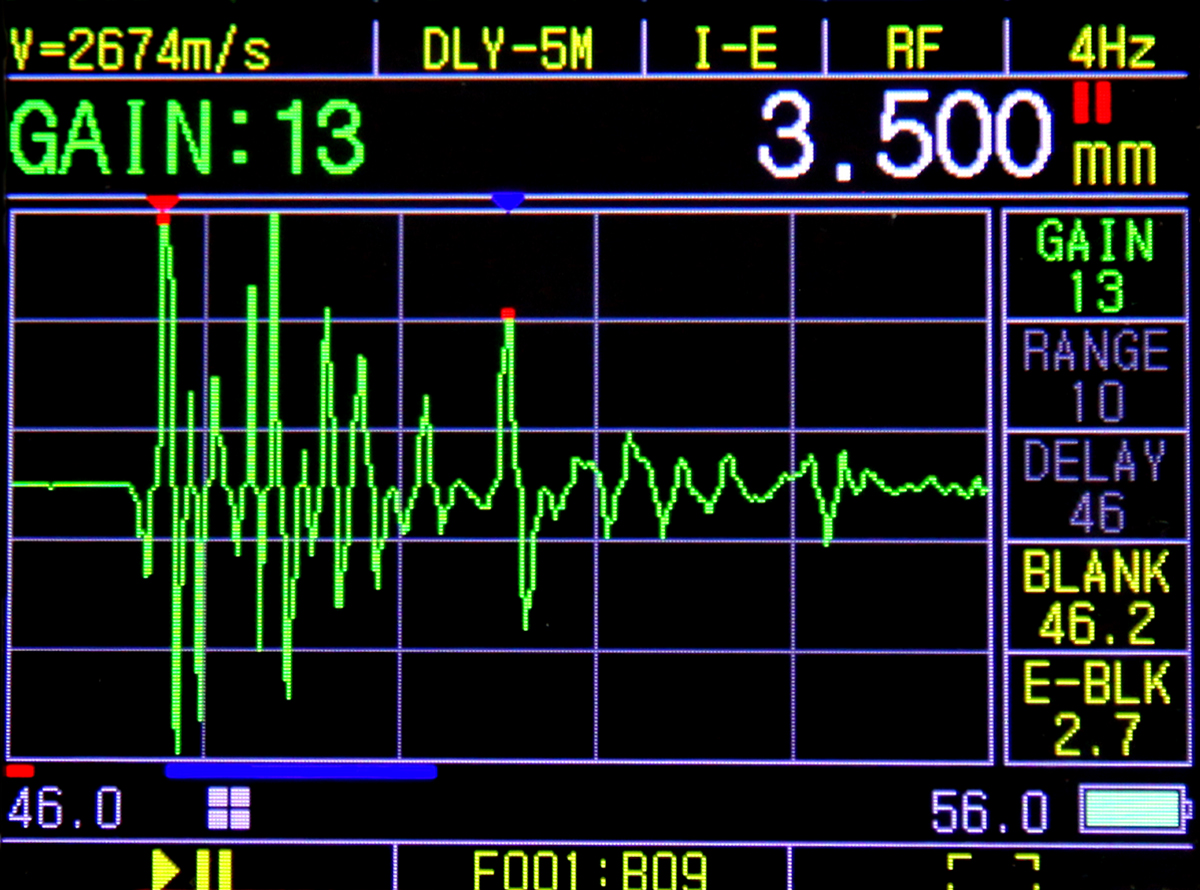

First, the water layer thickness between the immersion probe and the sample under test needs to be maintained appropriately. As the medium for ultrasonic propagation, water layer thickness directly affects the strength and clarity of the reflected signal received by the probe. The thickness of the water layer is adjusted so that the ultrasonic signal can be effectively propagated in the material and generate sufficient reflection when encountering the interface for the probe and instrument to capture and analyze.

Secondly, the ultrasonic probe must be perpendicular to the surface of the sample being measured. The tilt angle will cause measurement errors. If you find that the measurement waveform cannot always indicate the correct measurement value during the adjustment of the water layer thickness, you need to consider adjusting the probe angle.

In the ultrasonic thickness measurement of fiberglass, use the A-scan mode of the PM5 Gen2 ultrasonic thickness gauge. By simply setting parameters and adjusting the A-scan waveform display, you can avoid interference generated inside the material and obtain accurate and reliable measurement results.

If you want to know more about ultrasonic thickness measurement, or encounter difficulties in measurement applications, please feel free to contact us to provide you with solutions.